Manufacturers of Colored Mortar and Mortar Pigments

- flamingo-BRIXMENT

- Solomon Colors

- Lambert Corporation

- Lehigh Cement Company

- Ebonex

- Dynamic Color Solutions

Study the information on their web sites with respect to the proper techniques to employ when mixing and working with the colored mortars. They can be tricky!

Are you one of the manufacturers listed above? Do you want your company name to be a link to your website? Click here.

Several of the followings things can cause the color in your brick job to be inconsistent:

- Using premixed mortar from different runs from the plant - all bags must be from the same run or batch.

- Using different types of sand throughout the job.

- Using too much water in the mortar.

- Acid washing the brick.

- Using too much or too little pigment in each batch of mortar if adding your own colorant.

***!!!!!READ THE INSTRUCTIONS!!!!!***

Need to repair your masonry? Find a good contractor and learn the secrets of the trade with my Masonry Repair (Chimneys, Stucco & Brickwork) Checklist. I offer a 100% Money Back Guarantee.

Brick Manufacturers

You can find a list of over 100 brick manufacturers at the Brick Industry Association web site. Click the Resources tab; BIA Members tab; and Manufacturers tab. Choose ALL in the drop down lists to display a complete list. You can also search by state.

Most of these manufacturers have web sites with great product information and locations of local distributors.

Literature Sources and Installation Tips

Literature Sources

Some of the best literature, concerning brick and masonry construction, can be found in three different places: the Brick Industry Association; the Masonry Institute of America; and the Portland Cement Association. The Brick Industry Association (http://www.bia.org) publishes periodic pamphlets called Technical Notes on Brick Construction. These deal with just about any aspect of brick that you can think about. They also publish an incredible book called Principles of Brick Masonry.

Installation Tips

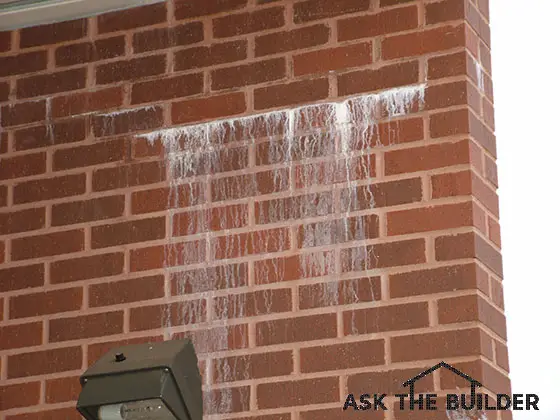

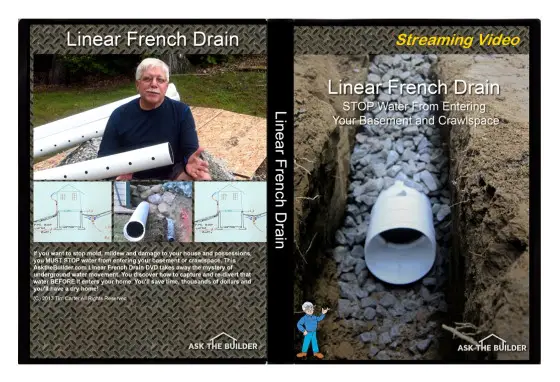

I could write pages and pages concerning installation of brick. The Brick Industry Association listed above has numerous books and pamphlets on this subject, as does the Portland Cement Association (http://www.cement.org). The key points are understanding that mortar is just like concrete. It requires special attention and techniques to achieve maximum strength. This is vitally important, as the mortar holds the bricks together!!! Brick veneer construction needs to be adequately attached to the walls behind the bricks, or else it might simply tip over and fall down. Flashing details and weep holes are important so water does not collect behind bricks. Start reading!

Tar and chip pavement surfaces are nothing new. In fact, there is a strong possibility that you have driven across hundreds of these roads. Many counties use this surface on secondary and rural roads. It is a cost efficient method of repaving and sealing an asphalt roadway.

Tar and chip pavement surfaces are nothing new. In fact, there is a strong possibility that you have driven across hundreds of these roads. Many counties use this surface on secondary and rural roads. It is a cost efficient method of repaving and sealing an asphalt roadway.