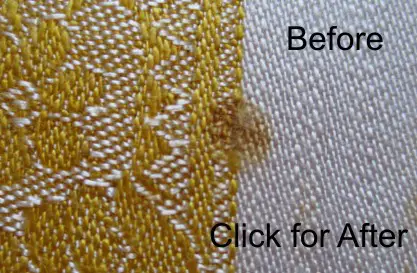

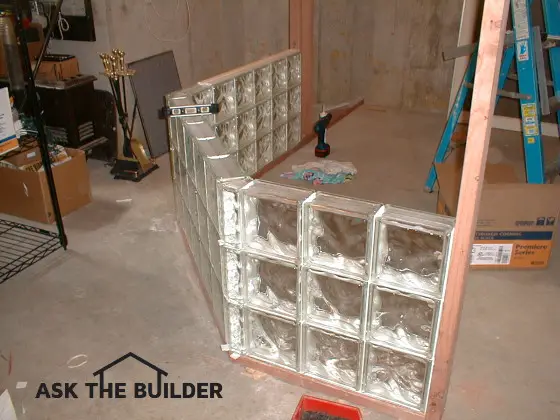

Glass Block Greenhouse | The Pittsburgh Corning glass block stack easily if the first course is plumb and level. Use their ProVantage plastic spacers.

Glass Block Greenhouse - So Easy With Caulk

DEAR TIM: I love the look of glass block and have several projects I am thinking about. One of them is somewhat bizarre - a playhouse for my children. But the process of building with the glass block intimidates me as I have never laid brick or block before. Are there some tricks you can share that will enable me to use this wonderful product that is sturdy but allows abundant light to get into spaces? Andrea G., Lexington, KY

DEAR ANDREA: Wow, did you hit the nail on the head, not once but twice! You have no idea how hard it used to be to work with actual glass block. It was installed in the same manner as brick and block using mortar and thin reinforcing steel.

Is It Hard to Install Glass Block with Mortar?

Yes, it's incredibly hard to install glass block using traditional brick or block mortar.

If you think laying brick and block requires skill, you have no idea how much extra talent you must possess to lay glass block in mortar. Brick and block have an invisible characteristic that actually helps masons install the brick and block. It is called suction.

What Does Suction Do?

The porous nature of brick and block is such that when the masonry unit comes into contact with the wet mortar, some of the water is instantly absorbed by the brick and block. It is similar to the way paper towels absorb spills. This suction allows the mortar to stiffen rapidly so that you can continue to lay course after course without disturbing the work in place.

Do Glass Block Have Suction?

Glass blocks have no suction whatsoever. The mortar mix must be the perfect consistency - neither too wet nor too dry. You can usually only lay a few courses and then must stop so that the accumulated weight does not squeeze out mortar in the first courses you laid.

Is There an Alternative?

Yes, there's an alternative way to install glass block using caulk and plastic spacers.

Instead of taking years to acquire the skills of a master mason, you can master installing glass block in minutes.

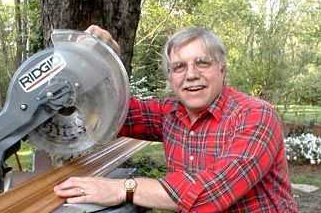

The better method is to put the glass block together the way I did when I recently built a glass block greenhouse for my wife's orchids. The glass block is the exact same one that has been used for years, but the manufacturer developed precision plastic spacers that create perfect horizontal and vertical spacing for the block.

What is the Most Important Step?

The most important step in the entire process is getting the first course of glass block both level and plumb. The manufacturer recommends, no insists, that you build a curb off the ground to install the first course. I did this by using a 2x6 piece of redwood that I got perfectly level using cedar shims. This level base made the installation proceed with absolutely no problems.

What is the Best Caulk to Use?

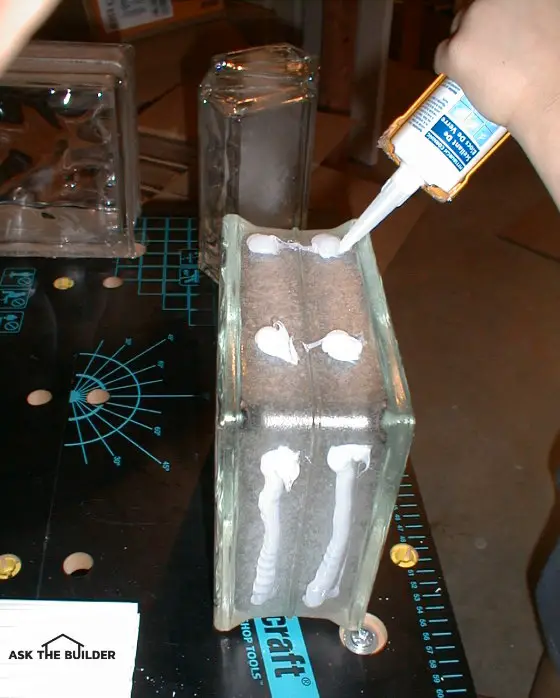

Silicone caulk is the best to use to install glass block. Instead of using traditional mortar to connect the block to each other, you simply use clear silicone caulk. I was amazed at how easy it was to assemble the block. In fact, it was so easy my 12-year-old daughter helped with the entire job. Not only did she apply all of the silicone to the blocks, but she also placed blocks on the walls. This amazing technology is both simple, effective and the end result will take your breath away.

My 12-year old daughter loved squirting the silicone caulk onto the block. Reference: June 22, 2014 Newsletter.

Do you Grout the Joints Between the Glass Block?

Once all of the glass block are in place and the silicone has cured for a short time, you grout the spaces between the block with a mortar-like material. It is nearly identical to sanded grout you might use for ceramic tile floors. Because of the super-smooth surface of the glass block, is very easy to wipe the excess grout film from the surface of the glass block.

Once the grout hardens, you can come back with a damp sponge and remove any light grout film. It is also advisable to take an old cotton towel and buff the surface of the block to make them crystal clear.

Watch this video to see how to grout the glass block:

Can Glass Block Create Other Projects?

Do you want to know how easy and fun it really is to use this new system? When my daughter and I installed the last block we both looked at each other and said, "What can we do next!" We started thinking of cool projects and yours was one that was discussed. The glass block system has special 90 degree outside corners that would allow you to easily build a square or rectangle playhouse for your children. I used special 45 degree angle block corners to create a cool clipped corner inside my greenhouse.

Glass Block Doghouse

Another project I brought up that everyone thought was off the wall was using the glass block to create two or three walls of a dog house. As crazy as this sounds, it just may have some merit. The glass block, silicone and grout are 100 percent waterproof. In colder climates when the sun is low in the sky, the glass would allow sunshine to warm the interior of the shelter.

An insulated concrete slab could capture and retain the heat. A large roof with generous overhangs would stop the summer sun from making the dog house into an oven. I'm sure you will uncover lots of cool projects to use this new glass block system if you stop and think about it.

This picture doesn't do the room justice. I need a wider angle lens. The blue sky and cloud ceiling panels rock!

Is This System Revolutionary?

This new glass block installation system is perhaps one of the coolest things I have seen in a long time. I saw it at a recent convention and was immediately attracted to it since I knew how hard it was to install glass block using traditional mortar. The plastic spacers are so well-engineered that the spacing between individual glass block is maintained perfectly as long as you apply the correct amount of silicone caulk.

Companion Articles: Glass & Acrylic Blocks Do Many Things, Glass Block Installation, Glass Block, Glass Block Manufacturers

Column 532