DIY Dining Table Plans| Who would think you could transform these cable reels into a dining room table in minutes? Keep looking below!

"You may find this hard to believe, but I can produce the sturdy table you need in one hour for less than $40.00."

DEAR TIM: It's a very long story, but I have a dining room with eight chairs and no table. Ten days from now, I am having a dinner party and do not have the thousands of dollars at this time to buy the table I really want. I have any number of oversized table cloths so whatever table I use will not really be seen. Money is really tight after the holidays so what in the world can I do? Mary R., Cincinnati, OH

IMPORTANT NOTE: Mary R. wrote to me after her party. Her letter is far below.

DEAR MARY: Oh gosh, you are in a bind! Fine furniture that can last generations can be expensive but it's also worth the wait. But as you outlined, that option is not on the table - pun intended! As desperate as your dilemma sounds, I've been faced with them before on past remodeling jobs where I needed to provide customers a temporary table. You may find this hard to believe, but I can produce the sturdy table you need in one hour for less than $40.00.

What Size Should My Table Be?

The economy table that will hide under your tablecloth needs to be eight feet long, 42 inches wide, and 30 inches high. These dimensions match those of most dining room tables that will seat 8 people comfortably: three on each side and a person at each end of the table.

A table this size can also fit ten people if they get a little cozy.

How High Should the Table Be?

The actual height of a table is fairly critical and is commonly matched to the height of the chairs. If you have a breakfast or kitchen table in your home, move one of your dining room chairs up to it, sit down, and check to see if you feel comfortable at the table. If so, the dining room table you are going to assemble should match that table height plus or minus one-half inch.

What is the Cheapest Table Option?

The cheapest dining table you can build will use a 4x8-foot piece of plywood and two large electric cable reels.

This affordable solution can be assembled with minimal ease requires two stops on your trip to acquire material. You need to visit a lumber yard and an electrical parts distribution business.

The electric parts business is one that typically sells all of its products to residential, commercial, and industrial electricians. These are the places where you will find circuit breaker panels, specialty switches, conduit of all types, etc. They almost always have hundreds of large empty cable reels back behind the warehouse. These reels sometimes are available for free or can be purchased for a very small fee.

What is a Cable Reel?

A cable reel is a round object that holds long lengths of electrical cable. It is the same thing you have on a fishing rod, but much larger. They come in all sorts of sizes and I know for a fact you can get ones that are perfect for your needs.

You need two cable reels that measure 29 inches wide and 25 inches in diameter.

Are Cable Reels Stable?

When you place these cable reels on their side, they make solid bases for the table top. The 29-inch width becomes a 29-inch-high platform when the reels are laid on their sides. You will then place a three-quarter-inch thick piece of plywood on top of the reels to create the actual table.

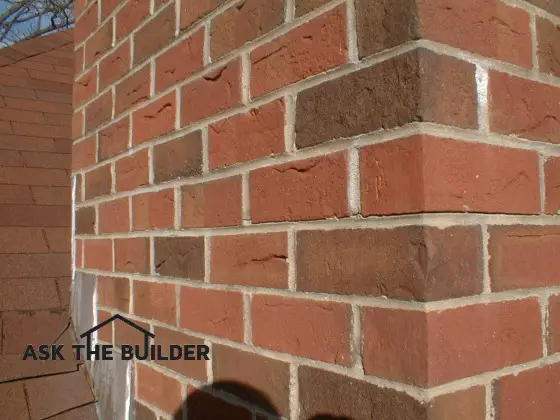

This DIY dining table was assembled in 10 minutes. The rest of the time was spent cutting the plywood and rounding the corners.

How Far Apart Should the Reels Be?

The reels should be placed in the center of the room spaced just one foot from each other. This will create 8.5 inches of overhang on the sides and a generous 17-inch overhang at each end of the table top. Once the plywood is in place, drive four 2-inch-long screws through the plywood into each reel to securely fasten the top to the reels.

How Do You Round Off the Corners?

When you cut 6 inches off the width of the 48-inch plywood to make the top, be sure to create a radius at each corner.

Use a simple wood rasp to round off the corners of the plywood. If you do not do this, there is a good chance the table cloth will tear if pulled against one of the sharp 90-degree corners. It's also a good idea to use some coarse sandpaper on the top edges of the plywood to remove any splinters.

This is the actual finished DIY dining table at Mary R's house!

Should I Stain the Reels?

If you have time, you can apply stain that matches your chairs to the lower half of the cable reels. This is not necessary, but it will help to complete the illusion.

Will You See the Reels?

I wouldn't be concerned in the least about the appearance of this temporary table. When the chairs are in place around the table, there's a very good chance you may not see the cable reels. If you're worried, use the same slight of hand magicians use. Direct your guests attention to a magnificent centerpiece arrangement in the middle of the table!

Mary R. wrote back after the party. Read her email to me below!

Can I Use Saw Horses?

If you can't find cable reels, you can use simple saw horses to support the plywood top. Many home centers have simple parts that allow you to create a saw horse using metal brackets and 2x4 material.

If you choose to do this, be sure you install diagonal cross bracing on the legs of the sawhorses. This bracing is additional 2x4 material that travels from the top of on leg to the bottom of the other leg on each sawhorse.

Without it, the horses can collapse without warning. An accident like this would be devastating while all the guests were halfway through dinner. Cable reels exhibit enormous stability. A table supported with these will rarely tip over.

January 30, 2004 - I am blessed to get wonderful emails from readers of my column. Here are two that provide great suggestions if you need to make an affordable table:

Pat Hutchison Author's Note: Pat, this youngster appreciates your advice! TC Jo Potter wrote to me and shared these great comments:

|

Mary R's Follow-Up Letter:

| February 17, 2004

Well, I just got an email from Mary, the woman who asked me the question that was the seed for this column. Let her tell you how well the table worked:

|

What is the Wood around the Windows and Doors?

What is the Wood around the Windows and Doors?