DEAR TIM: I have a wood deck, boat dock and picnic table that needs to be cleaned and sealed. I also just purchased new outdoor wood furniture. I have been less than satisfied with previous wood sealant products. Does my new wood furniture require immediate sealing or should I wait a month? What is the best way to clean and prepare wood to be sealed? Are certain wood sealants better than others? What is the average life span of a high quality wood sealant? Pat - Meredith, NH

DEAR PAT: I can absolutely understand your frustration with wood sealant products. There are many products all claiming that they are top performers. The sad truth of the matter is that many of them are inferior products. Fortunately, advancements in coatings technology has produced some synthetic penetrating water repellents that will make you quite happy.

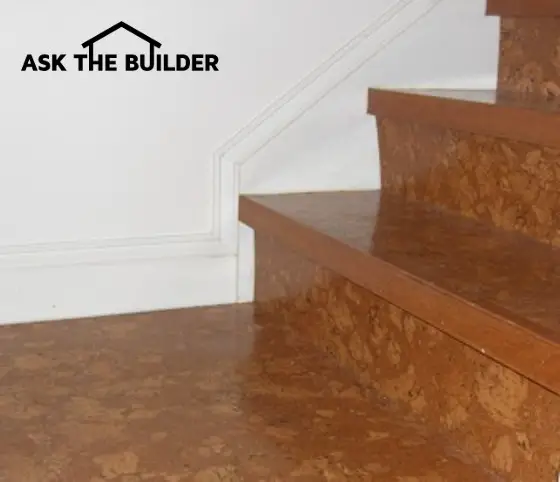

Wood that is used to construct boat docks, decks, handrails, picnic tables or any other horizontal outdoor surface is subjected to the absolute harshest weathering conditions. Unprotected wood absorbs enormous amounts of ultraviolet (UV) radiation from the sun. UV rays can actually blast apart lignin within wood. This is the glue that bonds wood fibers together. Rain water and snow melt can pond or pool on flat boards. This water can easily be absorbed by the wood causing it to swell. When the sun or wind dries the wood, it shrinks. The shrinkage forces cause cracking, twisting and warping. Conventional pressure treatment chemicals used in treated lumber will inhibit rotting but will not stop these other destructive and unattractive phenomena. New wood needs to be sealed immediately. Water and sunlight begin to destroy it as soon as it is exposed to these elements.

Cleaning a wood surface prior to sealing is very important. The cleaning will remove any dirt, tree sap, algae or mildew. It also will remove the decaying wood fibers destroyed by the UV rays. All of these things prevent the wood sealer from adhering or penetrating into the wood.

Do not use chlorine bleach (sodium hypochlorite) to clean your wood! It is a very strong oxidizer that will remove the natural color from your wood and destroy the lignin in the wood. In addition, chlorine bleach is highly toxic to any vegetation surrounding your deck. A neighbor of mine systematically tortured and killed a large tree next to her algae covered patio. She achieved this by using chlorine bleach to remove the green haze. Beware! Many off the shelf deck cleaners contain chlorine bleach. Study the product label before you buy. If you see the words sodium hypochlorite, this means the product contains chlorine bleach.

This handrail split was probably caused by not drilling a pilot hole for the screw. The screw had a sharp point and can easily create a tiny split in the wood when it is fresh and wet with treatment chemicals. But as the wood dries, the crack quickly widens as the moisture leaves the wood. Pilot holes will prevent cracks and splits in almost all cases. PHOTO CREDIT: Suzanne Wieczor

A much better cleaner for wood decks is oxygen bleach. This product will not remove the natural colors from the wood nor will it harm vegetation. Oxygen bleach kills mildew and removes algae and dirt from wood decks and other outside surfaces. This product is a powder that dissolves in water. Thousands of people use oxygen bleach each year to clean exterior wood surfaces.

Oxygen bleach should be used with moderate caution if it is used to clean redwood. It can sometimes darken the wood. This happens most often with freshly cut redwood that has a low pH value. As redwood ages its pH value becomes more neutral and the oxygen bleach will not darken it. The California Redwood Association recommends using oxalic acid to clean redwood.

Dirty and weathered cedar can be cleaned with oxygen bleach. The results are spectacular. Once clean, the cedar looks like new. Oxygen bleach also helps to remove mill glaze from new cedar. It opens wood pores so that your deck sealer will penetrate more deeply.

When selecting a sealer, try to choose one that is a penetrating water repellent. Look for ones that are formulated using synthetic oils and resins. Some are available that are water based. You can often clean and seal your deck the same day if you use a water based product. Choose a sealant that is moderately pigmented. The pigments in sealants do a great job of reflecting and absorbing harmful UV rays.

Many popular sealants found at paint stores and home centers contain natural oils like linseed oil, vegetable oil, animal fats, and tung oil. These natural oils are actually food for mildew and algae. To stop the organisms from feasting on sealants that contain natural oils, manufacturers have to add mildewcides and fungicides. Unfortunately, these chemicals are often water soluble. Rain and snow can dissolve them and wash them away leaving a deck unprotected. That is one reason why many decks turn black or green in just six to nine months. Synthetic penetrating water repellents do not contain food for mildew and algae.

| Message from Tim: |

Years ago while researching a column about cleaning decks, I discovered the wonders of Oxygen Bleach. It is perhaps the 'greenest' cleaner I know of as it uses oxygen ions to break apart stains, dirt and odor molecules. There are no harsh chemicals, and it works on just about anything that is water washable.

I decided to create my own special blend using ingredients made in the USA. In fact, the raw materials in the active ingredient are food-grade quality registered with the FDA. I call my product Stain Solver. I urge you to use it to help clean your deck surfaces. You will be amazed at the results!

Avoid using sealers that are film forming sealants. Beware of products that contain acrylic resins, varnish resins or alkyd resins. Look on the label for these ingredients. These products do not readily soak into the wood. They leave a film that will eventually peel. If the film peels unevenly from your wood surfaces, it will become a maintenance nightmare. You will have to strip your wood in the future to add additional sealants.

Be sure to follow the instructions on all cleaning and sealant products. Hot, sunny, windy days can be the worst time to apply certain products. Some synthetic water repellents will last up to 3 years if you apply them according to instructions. I have a synthetic water repellent on my front porch that is two years old. It looks practically like new. There is no sign of mildew or algae growth whatsoever.