Faux finishing can be done with simple materials found in your home.

DEAR TIM: I recently saw someone transform the walls of a typical drab room by using just paint and specialty glazes, some newspaper and regular painting tools. The effect was dazzling. What is really involved in doing faux painting? I also have a dreary, dark paneled family room. What can be done with that? Judy R., Falls City, NE

DEAR JUDY: Faux or "false" painting has really become popular. The reason, I believe, is straightforward. Just about any person who has some patience can create a multi-colored and often textured look that really catches the eye. I have seen some simple faux finishes done that look just like leather. If you become skilled in this craft, you can create marble, wood grained looks, stone blocks, etc. that can fool just about anyone.

Faux painting usually involves multiple steps. As you have noted, it requires minimal tools for most jobs and just a few special components. Large paint stores or home centers almost always carry the special glazes required for certain faux finishes. Some also carry unique tools that make faux finishes look professional.

The faux painting newsprint finish you saw requires that you apply a dark color on the walls as your base coat. The neat thing is that you control this color. It can be a green, perhaps a medium royal blue, or a bronze tone paint. The brown colors are the ones that will make your walls look like rich leather.

Want a faux finish but don't have time to do it yourself? Find the professional painters by using my Interior Painting & Staining Checklist. I offer a 100% Money Back Guarantee.

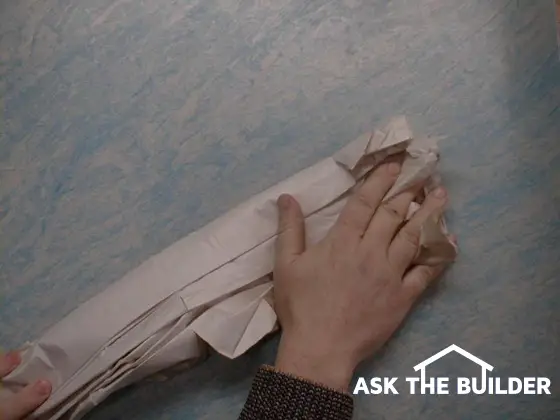

You need to visit your friendly newspaper printing facility. If you talk to the right person and show them your paid subscription bill, they will probably give you the necessary blank newsprint you need for your project. If you use regular newspaper that has ink on it, the ink will transfer to the walls. An average sized room, say 12 x 12 x 8 feet high will consume 125 to 225 twenty-four inch by thirty-six inch regular sheets of newsprint! You fold the newsprint accordion style or fan style before you begin to paint. All of the sheets need to be pre-folded before you start. If you waste time folding while you paint, the finishes will dry on the wall before you have time to work with them.

The next step is easy. You apply a cream colored glaze to fully dried paint. Lay a folded sheet of the newspaper at an angle and push it down into the wet glaze. Fold and unfold the paper until it is saturated with the glazing. Only work one wall at a time. Be sure to maintain the same angle as you work so the finish looks consistent. Step back frequently about six to eight feet and look at the results.

A faux finish can be made to look like genuine marble.

There are also some nifty paint rollers that will produce a similar finish. Some rollers that are available in stores have adjustments on them so a variety of finishes can be achieved with the same tool. You can even get instructional video tapes with some of the tools. These rollers save lots of time and may be just the ticket for a novice.

To avoid frustration, I would absolutely practice first on a 4 x 8 foot sheet of drywall in a garage or workshop. If you feel confident, then go inside and do a small closet. This will get you used to dealing with the corners. Get your technique down before you tackle your first room.

Dark paneling can be lightened easily with faux painting techniques. If the paneling has a grained or textured surface, you will end up with a dramatic look. You apply a light colored oil based paint that has been thinned 33 to 40 percent with paint thinner. The paneling must be clean, dry and wax- free. If it has a urethane or old varnish finish, this finish will need to be softened with a clear finish softener available at a large paint supplier. You apply the thinned colored oil paint to only 3 or 4 boards at a time and immediately wipe it off. It is a magnificent look once finished!

Related Articles: Faux Finishing, Faux Finishing Basics, Faux Finishing Tools, Faux Finishing Books, Faux Finishing Wall Paneling, Rag Painting

Column 254