This is the peak of my sun room roof. The upper six feet of it was horribly rotted from regular indoor humidity that condensed on the underside of the roof sheathing. The rot was much worse on the north facing roof that you see in this photo. The east facing side of the hip roof had only 50 percent as much rot.

Hip, Ridge and Soffit Ventilation

DEAR TIM: The buzz word in my area about new roof and re-roofing jobs is ridge and soffit ventilation. I don't remember seeing any of these products on the houses I grew up in. Are they really necessary? What happens if your house has a hip roof? A friend of mine who lives in the snow belt had one foot of snow accumulate in his attic because of these devices! I wonder if this ventilation trend is just a clever trick to sell something that is more trouble than it is worth. Charles P., Wahoo, NE

DEAR CHARLES: These new hip, ridge and soffit ventilation products are indeed clever. But don't think for a minute that they are a tricky gimmick sold by a motivated roofing salesperson or a builder. These products are innovative and an absolute necessity. New houses built without ridge and soffit ventilation can have serious roof rot problems. I know it for a fact as it happened at my own home.

The sun room at one corner of my house happens to have a cathedral ceiling that rises on two sides of the room creating a hip roof. One side of the hip faces east and the other side faces north. When I built my house 16 years ago there were no foolproof hip roof ventilation products available. I was very worried that the humidity created by the many plants in this room might cause a rot problem. This year my annual fall exterior walk around inspection revealed that my fears had come true. Serious wood rot had developed on the upper areas of the north face of this hip roof. See above photograph.

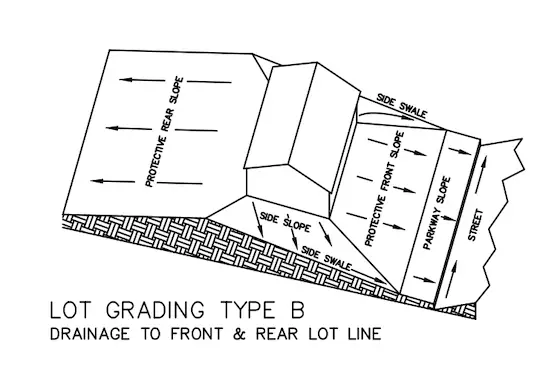

There are several good reasons why older homes did not have nor were required to have ridge and soffit ventilation. Older homes often had windows and doors that had no or poor quality weatherstripping. Air infiltration barriers had yet to be invented. The massive amounts of cold dry outdoor air would mix with the warm moisture laden inside air. The net result was that the indoor humidity in older drafty homes was far lower than indoor air you might encounter in your existing home. To make matters worse, as older homes are improved with new windows, doors and other energy saving suggestions they become condensation time bombs.

Since the wall systems of new homes and improved houses no longer leak air, the houses release the moisture into the attic spaces. If this moisture laden air is not quickly released from a cold attic the water vapor can condense on the cold wood surfaces in these spaces. If this happens wood rot will indeed happen as it did on my own house. Soffit, ridge and hip ventilation products allow Mother Nature to vacuum this moisture laden air from your attic with each puff of wind that blows across your roof.

As with most building products necessity is the mother of invention. Your friend that had snow in his attic probably had a low quality first generation ridge vent. Many of these allowed blowing snow and sometimes rain to enter attic spaces. New ventilation products are now available that will block snow and rain from entering attics. In fact, special hip vents can now be purchased that satisfy my tough demands. Hip vents are special because they need to have internal baffles that block snow and rain that can blow sideways across a roof. If you have a hip roof, be sure you install a special vent on these areas of your house.

The ridge and hip vents come in all flavors. You can purchase different colored metal vents that act as the cap shingles at the top of the roof. Other vent products are coils of plastic fabric that resembles coarse steel wool. My personal favorite is the hard plastic ridge and hip vents that are strong enough to stand on. These are applied over saw cut openings at the top of the roof or along a hip ridge. You then nail the roof shingles over the vents. Only a trained eye can detect their presence from the ground.

Column 335

Small Home Office Space

Small Home Office Space