Following Instructions Activity | Here's the finished product. They might not look great, but to a blind taste testing judge at a fair, I might get a blue ribbon!

Following Instructions Activity - A Builder Builds Biscuits

For decades, I've suggested to do-it-yourselfers that following instructions is vital to success. All too often when I do an autopsy on a project that has crashed and burned, it's evident that someone didn't follow instructions. Often they took a shortcut or felt they knew a better way than the manufacturer of the product.

Today I was forced to do something I'd never ever done before and it was imperative I follow instructions to the letter. Thank goodness it was a fun activity.

Hungry for Biscuits

Early this morning, I was texting back and forth with Mary Gene, the editor of my Adventures & Advice book series. Once the business part of the discussion was finished, I made a brief mention of how I had this craving for fresh, hot biscuits.

There was a pause in the conversation and the next thing I saw on my screen was a link to an online recipe.

These were biscuits I had to make from scratch. Never in my 67 years had I made any baked thing from scratch.

"Be sure you use COLD butter when mixing," Mary Gene emphasized.

I thought to myself, "Well, that seems to be too much work. I'll just melt some and pour it in the mix." There I was not following instructions and ready to go off the rails early in the process.

Fortunately, this grave error didn't happen because I texted back my brilliant idea about melting the butter.

"NO! The butter must be COLD." Mary Gene sent back.

Okay, okay, I'll use cold butter for goodness sake.

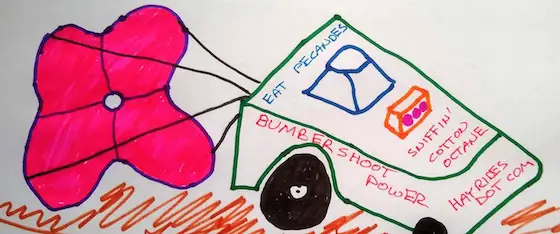

Mary Gene also said I could use knives to blend the butter if I didn't have the special tool shown in the recipe. I hadn't looked yet at the recipe and felt confident that I'd be able to find what I needed.

That's the magic mixing tool. It was hidden in a drawer in my kitchen.

Jeepers! Too Complicated!

Once in the kitchen, I looked at the recipe on my smartphone and grimaced. The author of the webpage had all this superfluous text before you got to the recipe and at first blush, it appeared to be way too complex.

"Why were we out of Bisquick?" I mumbled. It's just so easy to use that!

I looked over at the box of Grape Nuts cereal on the counter and exhaled, "Huhh, I can't have BBs again." Mary Gene introduced me to that comparison months ago because those crunchy small nuggets are like eating hard metal BBs if you don't allow at least 8 ounces of whole milk to work on them to soften them up.

I knew I had to dig in to make the biscuits because Mary Gene would ridicule me forever. When in similar situations, the sign over my high school football locker room appears in my head. It said, "Winners never quit. Quitters never win."

I was determined to win the biscuit game. It was time to follow instructions.

My Grandfather's Ghost

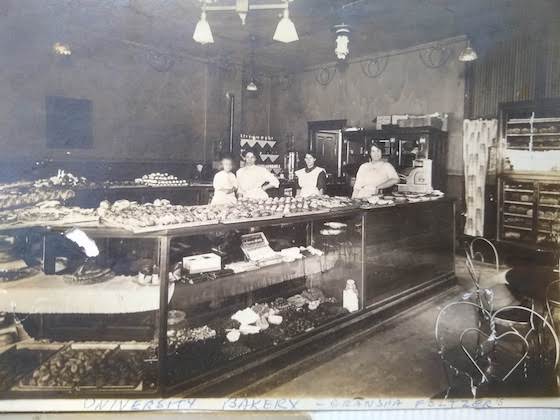

I also had a brief image of my grandfather. I never met him, but he owned a bakery with my grandmother in Cincinnati, Ohio just before the Great Depression. Here's a photo of it. Look at the case full of delicious fresh baked goods. There's no way I could let him down.

What a bakery it must have been!

It was time to focus and make it happen. After all, how hard could it be?

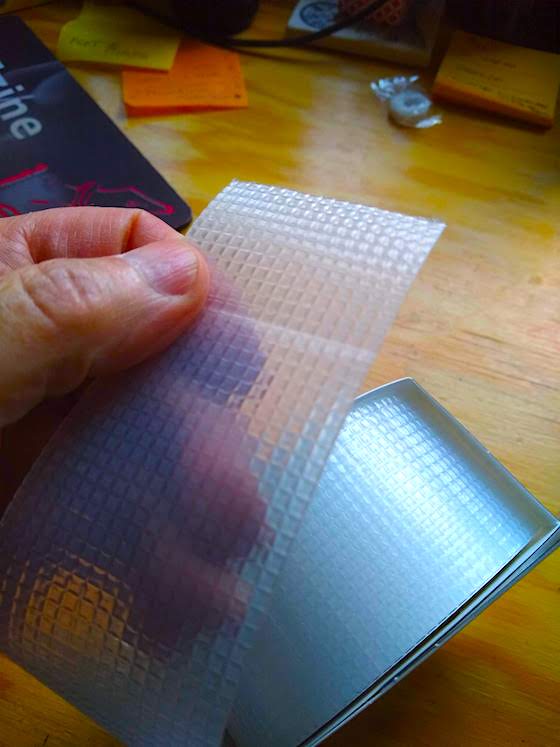

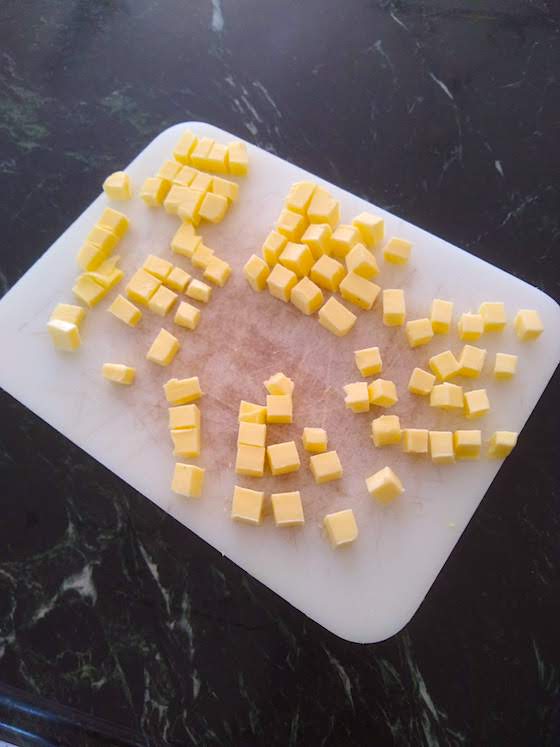

I took the time to read the instructions in the recipe. There was a note that the goal was to blend the butter pads so they became small butter balls in the dough. The recipe said to cut the butter up and put it back into the refrigerator until you were ready to blend it into the dry ingredients.

"Huh, I've got a better idea. Why not just cut the butter up now into small 1/4-inch cubes, separate them and then put it back in the refrigerator to get cold?"

Here are my butter cubes.

The recipe didn't say I couldn't do this, so being a brave new baker boy, I took a chance. My grandfather, no doubt, was smiling up in Heaven.

Splitting the Recipe

When I saw the recipe called for three cups of flour, I thought, "No way. That's way too much." I made an executive decision to split the recipe in half. How hard could that be? After all, I didn't go to summer school for math, but I did for Latin. Fortunately, the instructions were in English.

I was now in the zone. The flour, baking powder, salt, sugar were all blended and it was time for the butter. I slid it into the mixing bowl and started to use the correct weird tool. I then added the milk and single egg and stirred.

Here's the blended dough. You can see the butter cubes.

Perfection! The dough looked just like what Bisquick looked liked mixed up.

Baked Deliciousness

I dusted the marble island top with flour, put the dough ball on, dusted it with more flour, and used my hands to flatten it out to about 3/4-inch thick.

I found a biscuit cutter, cut the rounds, recombined the remaining dough, and seconds later ten biscuits were going into the oven.

I know, I could have taken it to the edge! I'm a rookie, after all.

Victory!

I removed the golden-brown discs from the oven just in time, let them cool, and then cut one in half.

I drizzled on some honey and bit into it. OMG, it was slightly crunchy - I liked that! - and it was delicious.

It was by far the best biscuit I'd ever eaten.

The moral of this story is to listen to your editor, and follow instructions if you want success and the best biscuits in the world!