Secret Hiding Places - Is this just a small pantry or do all the shelves roll out and rotate to the right giving you access to a tiny room behind the wall? Use your imagination. Copyright 2024 Tim Carter

Secret Hiding Places in Your Home are Everywhere

I’m in the final stages of writing a book that contains hundreds of hacks that you might want to incorporate into your existing home or a new one you’re building. I got lots of help from many of my newsletter subscribers, who shared some of their best ideas. It’s been a fun project.

The two categories that received the most response were electrical and secret storage. Thousands of homeowners need help with electrical outlets and switches they feel are in the wrong place. The original electrician didn't consider the best locations for outlets and switches. You, or a more clever electrician, can rectify some mistakes.

Hidden Staircases and Secret Passages

You may be a homeowner who desires to hide small and large things in your home. You may even take it to another level altogether and be like me. I dream of having at least one secret staircase and any number of hidden passages in the next home I build. Think of the game of Clue™. If you’re in the kitchen, you can magically be across the board in the study. Yes, it’s possible to incorporate secret passages in houses, but that’s a column for another day.

Here's a real-life secret passage in a kitchen.

There's a better way to disguise the seam on the countertop. This, done by an expert, would fool 999 people out of 1,000.

I’ll share with you a few of the ideas that my subscribers sent to me. The best ideas, of course, will be in the pages of my book. I think you’ll enjoy what I’m about to reveal. It’s important to note that you need to get in the mindset of a magician to conjure up the most creative secret places.

Void Space Between Walls

One of the easiest ways to create a small hidden space is to create a void between two walls. This needs to be done so that when you’re in each room, you think the wall you’re looking at is a common wall with the room next door. I have this situation in my own home now, where two large metal chimneys pass through the second floor up to the roof.

One of the walls is the back wall of the second-floor bathroom. The other wall is inside a closet in the bedroom next to the bathroom. You automatically think the two rooms share a wall. You’d be wrong. There’s a space about 24 inches wide between the two walls! The builder could have created a cutout in the hallway to this space. You could cover this opening with a large wall hanging or picture. A French cleat is best for holding the artwork against the wall.

False Bottom in a Window Seat

Window seats are an ingenious way to conceal long items that might only be 3 inches tall lying on their side. You can create a false bottom in the seat. Imagine flipping up the hinged window seat and seeing the bottom. Who’s to say there’s not another six or eight inches of space under this bottom? There are many ways to hinge the false bottom so it flips up when you need access.

Mayonnaise Safe

Do you need to hide some cash, jewelry, or other bibelots that have sentimental value? You can store them in your refrigerator. Did you know you can get a small can of latex paint the same color as mayonnaise? Carefully clean an empty jar. Be sure you don’t ruin the label. Let it dry, and then pour some paint into the jar. Roll it around to coat the inside. Let it dry well, and alakazam, you can store valuables in the last place someone might look.

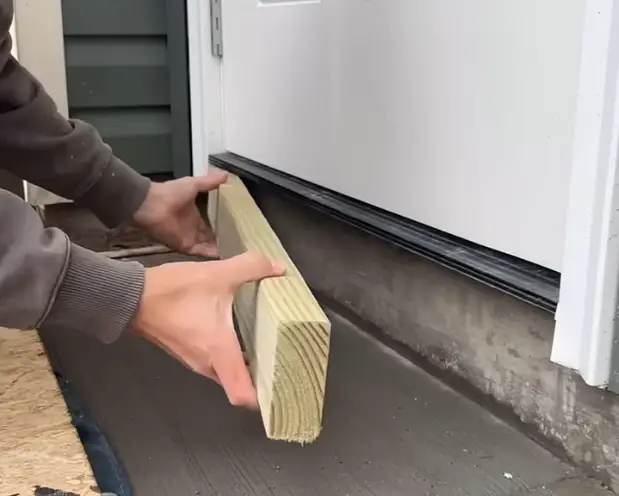

WorkBench Drawer

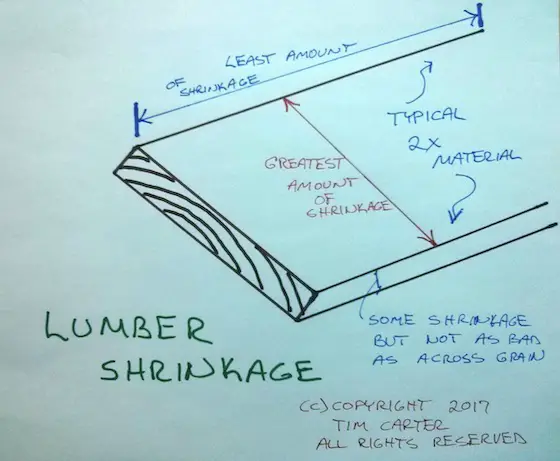

Do you have a workbench in your garage or basement? Is the top supported by a ring of 2x6s? If so, transform the front or side piece of lumber into a drawer front. Think of how the drawers work in the metal tool cabinets mechanics use. That same heavy-duty hardware can support the weight of a vast amount of thin, heavy items.

This simple, yet sturdy workbench was cut and assembled in less than 30 minutes! Photo Credit: Tim Carter

Paint Roller Safe

Here’s one of my favorite ways to hide small items of value in plain sight. Purchase a cheap paint roller with a 3/8-inch nap. Get a crappy roller frame and paint pan while you’re at it. Pour some paint into the pan and roll it around as if you had painted a room. Get paint on the roller frame handle. Create the illusion that you used the tools.

Brush out any paint from the pan as you would if you were going to clean it. Remove the roller cover from the frame. Stand it up on end and allow everything to dry for days or a week or two. Start to slide the roller cover back on the frame and look at how you have a tube to hide rings, small jewelry, cash, etc. Just be sure no one throws away the roller and cover that you now place on a shelf and throw other crap on it to hide it.

The Old Book Trick

Go to library book sales. You can often get thick hardback books for a dollar or less. Do what you’ve seen in the movies. Glue the pages together and cut out the book's center to create a void space. Complete the illusion by stacking this book with 30 or 40 others you purchased at the sale. I have a stack like this out in my garage on a shelf.

I challenge you to come up with some creative ideas. If you want to share them to help others, I can include your idea in my book and give you credit. Just share it via the Ask Tim page on my website. Happy Hiding to you!

Column 1554