New subscriber? Well, you picked a pretty special issue as your first one!

Distinguished subscriber of old? Pop the corks, pull the tabs, or unscrew the caps. Party time!

25th Ask the Builder Anniversary

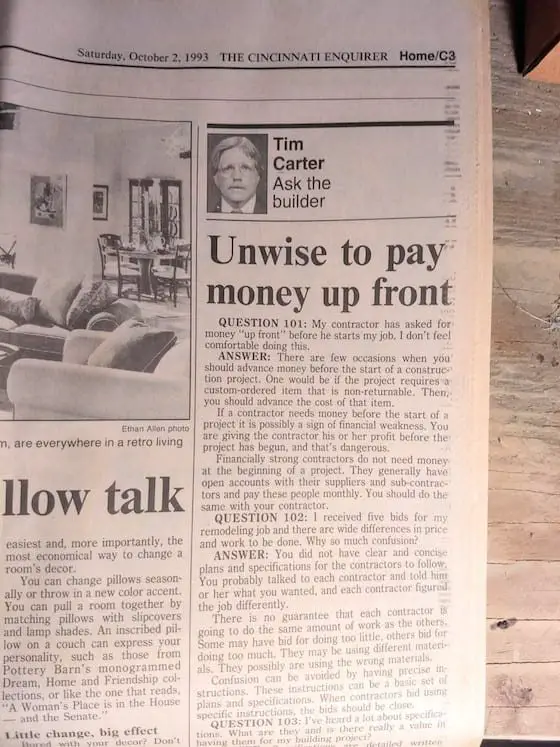

It all started twenty-five years ago on a dark Saturday morning. I was waiting outside at the curb for my newspaper carrier. He must have thought I was nuts when he handed me the paper through his car window.

I wanted to see my first Ask the Builder column in print. I was alone and everyone else was asleep at the house as I came inside and opened the paper.

Can you believe it's been twenty-five years? Wow!

CLICK HERE to read a special column I wrote about this special day.

Connections - How it All Started

Here's how Ask the Builder was born. It's important to realize I had always wanted to write a book about how homeowners got the shaft from some builders.

This frustration bubbled to the surface frequently for me. I'd give a quote for a job and often I was the high bidder. I'd explain to homeowners my number was right and that the other bidders might be putting in artificially low allowance numbers or they might be cutting corners.

Sometimes homeowners believed me and sometimes they didn't.

One Saturday in the late fall of 1992, I was in Dayton, OH, with my wife, son and oldest daughter Meghan. She was participating in an Irish dancing fesh or contest.

I was sitting in a folding metal chair and two chairs over was another dad. Somehow we got to talking and he found out I was a builder and remodeling contractor. I'll never forget his name, Biff Roberts.

"Tell me, do you use nail guns?"

"Oh yeah. I LOVE them. They save so much time and increase productivity!"

"Which one(s) do you use?"

"Are you kidding me? There's only one nail gun to use, Senco."

It turns out he was the head of marketing for Senco. Not too long after, he nominated me to Remodeling magazine as one of the Big 50, a huge award and honor. I had NO IDEA this was in the works.

In May of 1993, I got a phone call from Remodeling magazine telling me I was selected as one of the Big 50. I thought it was a prank call from Sister Susan who ran an orphanage in Jamaica. That's a long story for another day.

It was no prank. Several months later Kathy, my wife if you're a new subscriber, said, "You should take your book idea and write a syndicated newspaper column."

I saw a vision when she said it, went into my office and proceed to write three columns. The following Monday morning I walked into the newsroom of the Cincinnati Enquirer and found the home editor, Ann Haas.

She loved the columns and said she wanted to buy them and start running me each week. She also encouraged me to sell the column to other papers.

I took her advice and by the end of 1993 I had self-syndicated Ask the Builder into about 30 newspapers. Eventually about 120 papers across the USA were running the column.

It still runs today in about 60 USA papers.

That's my story and I'm sticking to it!

Big Party Promo Code

To help celebrate, Kathy and I decided to have a very big sale on all of the electronic products and consult services at the shopping cart.

Use the following promo code to get a RARE 25% off just about everything at my shopping cart. The sale ends in one week.

25ATB

If you're a seasoned subscriber you know the last time I've had a sale on just about anything in my shopping cart was eons ago.

Now's the time to grab things of all sorts that will help you save time and money and help you find the right contractor.

Do yourself a FAVOR and browse through my cart. You'll be stunned by what you'll find!

How about the Structural Basics Handbook?

How about my PDF copy of my Roofing Ripoff book?

Is water leaking into your basement or crawlspace? You can get my Linear French Drain Stream Video for 25% off!

How about a rocking set of plans for a deluxe shed? Yep, I've got them.

CLICK HERE and start browsing.

The promo code will not work on the Stain Solver you see, most of the other DVDs and maybe one or two other items.

But believe me, it will work on about 98% of what's in the cart.

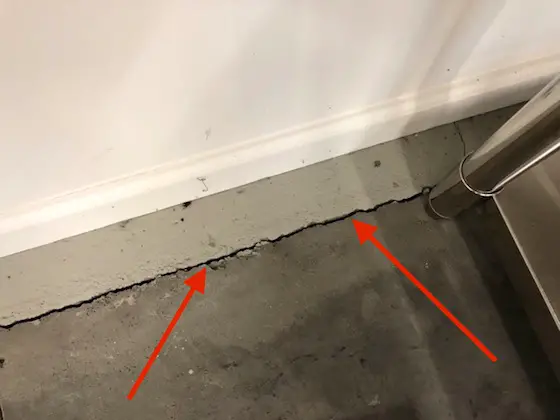

Concrete Cracks - Why and How to Prevent Them

I just revised this column this morning. I GUARANTEE you'll discover something new that will save you lots of anguish. CLICK HERE to save money.

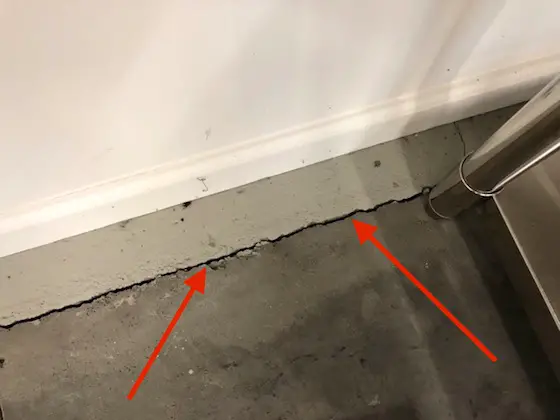

This is a concrete shrinkage crack. The concrete touched the lighter gray foundation the day it was poured. Over a period of months, even up to a year or more, the concrete slab shrinks in size. Copyright 2018 Tim Carter

That's enough for today.

Thanks for hanging with me for twenty-five years. If you've got an Ask the Builder story to share, or I've helped you in any way, PLEASE share it in a comment at the bottom of the anniversary column page. CLICK HERE.

Tim Carter

Founder - www.AsktheBuilder.com

Magic Cleaner Man - www.StainSolver.com

Radio Man - www.W3ATB.com

Do It Right, Not Over!