A silly little mouse caused this damage. You'll be suprised when you file a claim if you have similar damage. (C) 2023 Tim Carter

Homeowner Insurance Nightmare Catch 22

Do you have homeowners insurance? How much do you know about your policy, or should I say contract? When was the last time you read your policy cover-to-cover? If you’re like me, you purchased a policy sight unseen assuming that you and your possessions are protected in case of a fire, flood, storm, water leak, etc.

If you have a loss, there’s a very good chance you’ll suffer a secondary shock when you discover your policy has more holes in it than the colander in your kitchen cabinet. I know because it just happened to me.

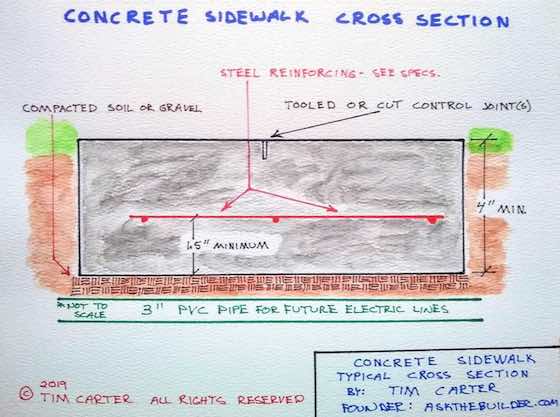

Seven months ago a mouse caused an overnight water leak in my home. The hardwood floor in our bedroom buckled and a floor beneath it was also damaged. Some drywall had to be repaired and replaced. All the flooring in the first floor of my home had to be refinished to match the replacement hardwood installed in the bedroom. The total loss was just under $30,000.00.

I soon discovered several things. First and foremost my insurance agent was worthless. She told me on the phone she couldn’t do anything about the claim and that I had to deal with the insurance company. My insurance company then offloaded me to a third-party adjuster. If I had questions, the adjuster was to answer them even though my contract was with the insurance company.

The damage occurred on March 23, 2023. I didn’t get a written estimate from the adjuster until May 18, 2023. The adjuster encouraged me to get bids when he visited my home days after the leak.

It’s a good thing I didn’t sign any contracts because his stern authoritative letter that came with his estimate informed me that if the repair cost was higher than his estimate, the insurance company would not pay for the overage unless it was pre-approved.

Three weeks before the adjuster’s estimate arrived, I did get a check from the insurance company for a little over $14,000.00. That was $1,000 lower than just the cost to do all of the floor restoration work.

Before I go on, let me ask you something. Do you happen to have $10,000, $15,000, or $30,000 in a checking or savings account you can tap into without causing you financial stress? I’m talking about money you could use to pay contractors to do work on your home. My insurance company expected me to have this and if I didn’t they told me to take out a loan or pay the contractors with my credit card.

After the restoration work was complete, I submitted all the invoices to the adjuster. His company came back and said, if you want all the money due to you, you need to provide us with the canceled checks you wrote to the contractors. I said, “I can’t pay the contractors until you give me the money you owe me.” It was a stalemate. Catch-22

A month of back-and-forth communications got me nowhere. Out of frustration, I filed a complaint with the New Hampshire (NH) Insurance Department. Within 48 business hours of their intervention, a FedEx driver handed me an envelope with the money I had deserved to get months before.

The bitter experience with my insurance company lit a fire inside me. I reached out to my state representative. She was keenly interested and three weeks later I was sitting in a chair next to the NH Insurance Commissioner and his top staff members. The commissioner wanted to know exactly what happened with my claim and he was most interested in the reforms I proposed.

My first suggestion was to require insurance agents to do what real estate agents are required to do in most states. An insurance agent should be forced to produce a one-page agency document that informs you their fealty is to the insurance company, not you. It should clearly state what the agent’s responsibilities are and where they end.

My second idea is that insurance companies should be forced to produce a simple bullet-point list of all the things that are and are NOT covered in the policy you’re about to purchase. In your lifetime have you ever received this list before purchasing a policy? Can you see how invaluable this would be allowing you to compare one policy against another?

I then recommended that the insurance companies should release money much faster. It should be just like in the home-building industry. When I delivered notarized affidavits to a bank or savings & loan, they issued a check to that contractor or supplier. My insurance company, once the heat was turned up by my state insurance department, cut a check in 30 minutes and I had it the next day!

Lastly, insurance agents and companies should be forced to give you, the day you file a claim, a roadmap of what to do, what not to do, and how long the process will take under normal circumstances. I had no guidance whatsoever.

Column 1529