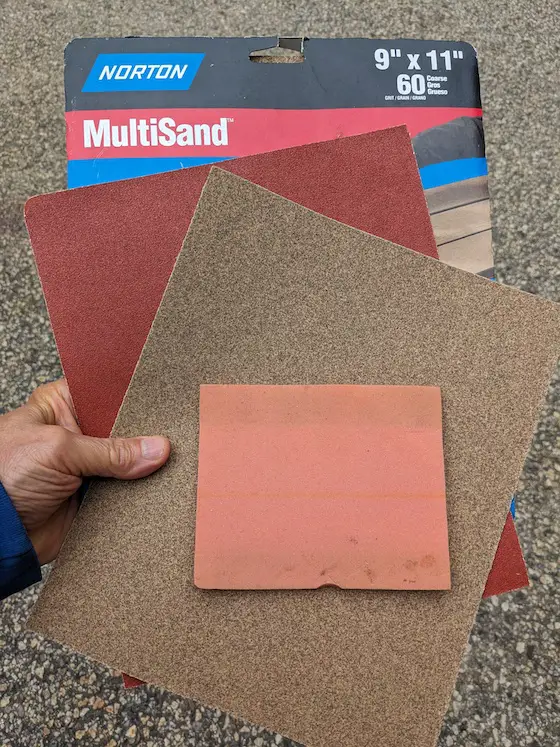

These are just a few samples of the many types of sandpaper in my shop. The small one is a flexible pad made to sand three-dimensional shapes. Copyright 2023 Tim Carter

How Much Do You Know About Sandpaper?

I’m thankful to have had enough trips around the sun that my adult children are finally calling me asking for advice about their projects. I hope you’re blessed to experience this transfer of knowledge. First things first, it’s a real treat to help them avoid mistakes followed closely by the warm feeling I get knowing they reached out to me rather than watch some unknown person on YouTube.

Just days ago my youngest daughter called me from 3,000 miles away. She had just purchased a used chest of drawers she wanted to refinish. She didn’t like the color one bit and was going to sand off the old finish.

“Sweetheart, sanding off an old finish is fine for wood floors where you can use a big drum sander. It’s really hard to do this with furniture. I suggest you use a liquid stripper to remove the finish and some of the stain. Once the wood is dry, then you can start to sand.” She hadn’t even considered stripping off the clear finish with a liquid. I suspect she had never seen it done before. Little did she know I did this fifty years ago with her mother as we used to collect and refinish antiques before we were married.

A second call came a day later asking about what sandpaper to use. My daughter had gone to a big box store and was overwhelmed by the selection of sandpapers. Perhaps this has happened to you. It can be daunting.

Chinese Invented Sandpaper

The origin of sandpaper has been attributed to Chinese craftsmen. They blended natural gum with crushed seashells and sand and applied this paste to parchment paper. While crude, it was an ingenious tool used to make wood quite smooth.

Seashells are simply calcium carbonate which has a hardness of only three on the Mohs hardness scale. While this is low, it’s hard enough to smooth just about any wood those ancient craftsmen were working with. My guess is they discovered that certain types of sand had a hardness much more than the seashells. There’s a good chance they found that quartz sand, with a hardness of seven, did a fantastic job of transforming rough wood surfaces to those that rivaled glazed pottery.

Natural and Man-Made Abrasives

The modern sandpaper you see at hardware and paint stores is made from a combination of natural and man-made abrasives. Red garnet is a natural mineral and a favorite of woodworkers. The tiny garnet particles get rounded off as you use the paper. As they dull, the garnet works to burnish the wood producing a highly polished surface. Red garnet sandpaper has a distinctive reddish-orange color.

Should you want to polish metal, you’d do well to work with emery cloth. The finer grades can polish most metals to a mirror-like finish.

Aluminum Oxide Self Sharpens

In my opinion, the workhorse abrasive is aluminum oxide. Sandpapers made using this material have a light or medium-brown color. They’re extremely common and work well to sand most materials around your home including wood, plastic, drywall, and hardened paint.

Aluminum oxide is the opposite of garnet. As you use aluminum oxide sandpaper, tiny fragments break off creating a new sharpened edge. Think of it as self-sharpening. It’s remarkable when you stop and think about it.

The grit numbers refer to the size of the particles that are doing the sanding. The lower the number the coarser the grit. A sandpaper that is 60 grit might have particles on it the size of table sugar. A 220-grit paper might have pieces that match finely ground pepper. Look at an individual piece of sandpaper and you’ll notice the particles are just about all the same size. This is by design.

The abrasive particles are processed through a sifting machine much like gravel is sorted and sized. When it comes to sandpaper the grit number refers to the number of particles that fit through a certain size screen that measures about 1 inch square.

Ultra-Fine Grit Polishes Wood

Some grit is so fine it resembles baking flour. Fine abrasives are used to create high polishes. The coarse grit is used to remove lots of material quickly. When speaking with my daughter, I suggested she try 120-grit paper first and see if it was too aggressive. My thoughts were the chest of drawers was made from pine. It’s a very soft wood and a coarser sandpaper can scratch it with ease.

I told her once she tried the 120 grit then switch to 220. That grit is considered very fine. That said, my final advice was, “Once you finish with the 220, try a piece of 320-grit red garnet paper. You may discover it makes the pine as smooth as a piece of glass.”

If you’re applying a clear finish to wood, it’s vital you get the wood as smooth as possible. If painting wood, you don’t have to invest as much work as the thicker paint film can fill and bridge fine scratches created by sandpaper. In fact, small scratches can actually help the paint hold onto the wood better.

As with most home improvement projects, you have to know what to do and when.

Column 1520