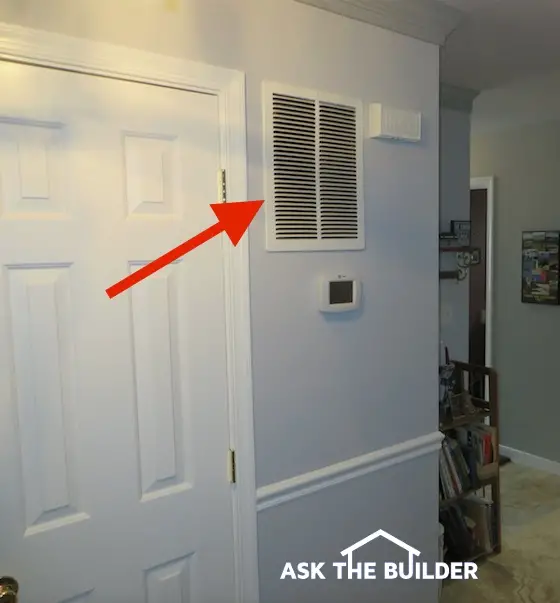

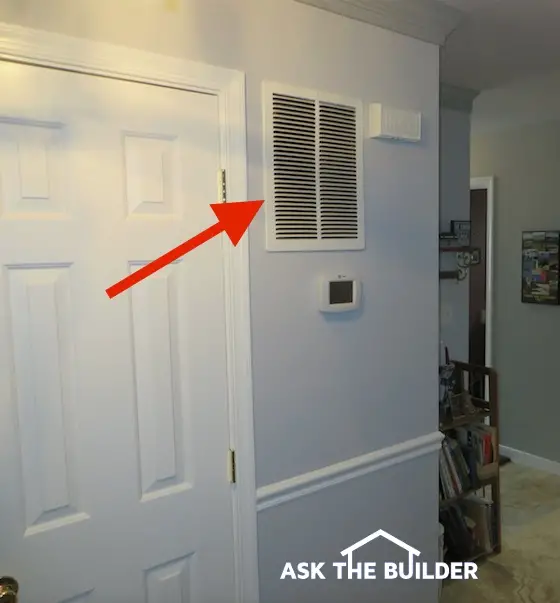

The red arrow points to a large wall-mounted return-air vent. The furnace or air handler is probably on the other side of the wall behind that door. How many return air vents should be in your home? The number MAY SURPRISE YOU! Copyright 2018 Tim Carter

HVAC Return Air Ducting - You Better Have One in Many Rooms

"An HVAC return air duct should be in every room except a bathroom and kitchen. They should be on interior walls across the room from the supply ducts that should be washing exterior walls with conditioned air."

Get FREE BIDS in hours from local HVAC companies to have new return air ducts installed in your home.

HVAC Return Air Ducting TIPS

Two years after this column was published, it was still receiving comments. So Tim shared it again in his June 23, 2019 Newsletter.

Should HVAC Return Duct Be the Same Size?

The air ducts in your house should be designed exactly like the blood vessels in your body.

Think about it. Half of the blood vessels supply blood to every part of your body all the way to the tips of your fingers and toes. The other half of the vessels return the blood back to your heart. Along the return trip back towards your heart, the blood gets resupplied with oxygen and your heart sends it back out again.

Have you ever wondered how blood pressure can be measured accurately at the tip of your finger? This magic happens because the blood-vessel diameters decreases as they get farther away from your heart.

Your heart, like your furnace fan, creates a finite amount of energy each time it pumps. As blood is delivered to your shoulder, there's less energy left to deliver the remaining blood down your arm. If the blood vessels all the way to your fingertips stayed the same size as up at your shoulder, there wouldn't be enough energy to push all that blood and maintain the pressure at your fingertips.

Mother Nature designed your body this way for a reason. Your HVAC person needs to do the same thing with the supply and return ducts in your home!

If an HVAC installer laughs at this concept, show him to your door. He's not a professional and he doesn't know the most basic things about fluid, yes air is a fluid, dynamics!

What's the Best Location for Return Air Ducts?

Supply air from furnaces and air conditioners should be on outside walls. The return air vent openings need to be on the opposite side of the room so the conditioned air is pulled across the room.

If the supply ducts are in the floor, then the return air should be located up high. This pulls the air across your body.

If the supply ducts are high or in the ceiling, then the return-air ducts or grills should be low on a wall.

FREE Call From Tim Carter About Your Ducts - Set up a Call with Tim.

Related Links

Cold-Air Returns - Be More Comfortable

Static Pressure In Supply & Return Ducts Is Important

My House is Hot or Cold. Is This a Return-Duct Issue?

Yes, if your house is either hot or cold, I'll bet you have inferior or lacking return air ducts.

If you live in a home that has rooms that are either too hot in hot weather or are cold in cold weather you could have a return-air duct issue.

Return air ducts are necessary for just about every room. However, there are two rooms that I never place return air ducts - kitchens and baths. Let's try to keep the garlic odors and hairspray in these rooms if you don't mind!

The reason for return air is simple. Your furnace is simply a recirculating pump. Instead of pumping water, it is pumping air.

We need to get the air back to the pump. Furthermore, without a return air duct in each major room, the supply duct air has to "push" all of the air in the room out of the way as it makes its way towards you. The return air ducts help pull the air as it is being pushed.

An HVAC return air can be in the floor, but they work much better on walls up about 7 feet. It's best to put them on an interior wall across the room from the supply duct. © 2018 Tim Carter

Where Can You Put Return Ducts?

If you have an existing ranch style home, installing return air ducts in each room can be done fairly easily. You do what we do in new homes.

You use the wall cavities as the duct. Think of it. Drywall that is nailed to 2x4s is really a duct - a box with 4 sides. All you have to do is cut out the floor immediately below the wall cavity as well as the bottom wall plate. Once you have created the opening, sheet metal will allow you to connect this to your existing return air system.

Two-story houses can be more of a challenge. You have to figure out a way to get return air from the ceilings of the second floor to the basement or furnace room.

Do you have a laundry chute that you don't use that often? Can it be sacrificed for the cooling cause? We have used these with tremendous success.

Sometimes, you can use a kitchen pantry closet or a hall closet. We have often been able to put a duct in one corner of the pantry or closet. This duct extends up to the second floor where it often lines up with an interior hallway wall.

Often you can collect the ceiling air through a network of flexible pipes in an attic. These pipes join together in one central location that permits you to run a duct down to the basement or a second-floor closet.

As a last resort, you may have to put a duct in the corner of a room(s). These can be drywalled easily. To effectively disguise it, you may build another one several feet down the wall. Shelves can be put between these two "stacks". If they are in a child's room, they can often be painted in a decorative manner as if it was intended for them to be there.

It was common in many older homes to have projections in rooms such as this. These bump-outs often were fireplace chimneys as they rose through to the roof.

How Do You Balance Return Air Flow?

If you want to really have a way to get the most bang for your return air buck, think of installing grill covers on the wall that have operating louvers. This will allow you to choke down rooms possibly on the first floor that are drawing too much air.

This, in turn, creates a greater suction in the rooms that really need cool air. This principle is no different than dampers which are used on supply lines to regulate airflow.

The grills with louvers are inexpensive and effective. On an older existing home that is being retrofitted for central air-conditioning, they are a must.

Go HERE to get FREE BIDS in hours from local HVAC companies to have new return air ducts installed in your home.

Do Old Homes Have it Backwards?

Do you have a house that is approximately 80 years old? If so, your supply ducts may be on inside walls. You may have a single giant return air grill on the floor or at the bottom of a staircase. This is all wrong.

Supply ducts should be located on outside walls, preferably under windows and near doors. The intent is to wash the exterior walls with heated or cooled air. You are trying to combat the heat or cold at its source.

The single giant return air grill in the floor balances the load at the furnace motor but does nothing to promote cross-ventilation in each room.

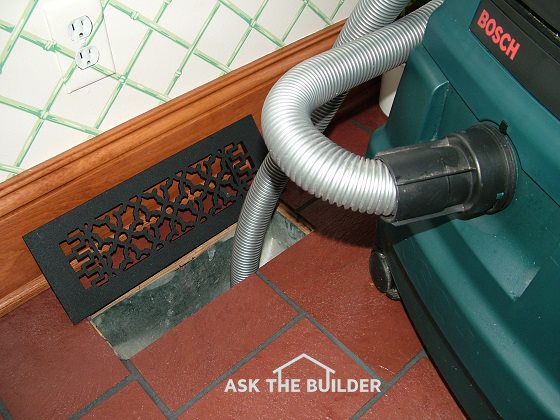

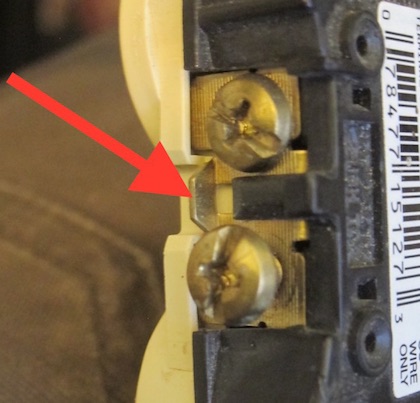

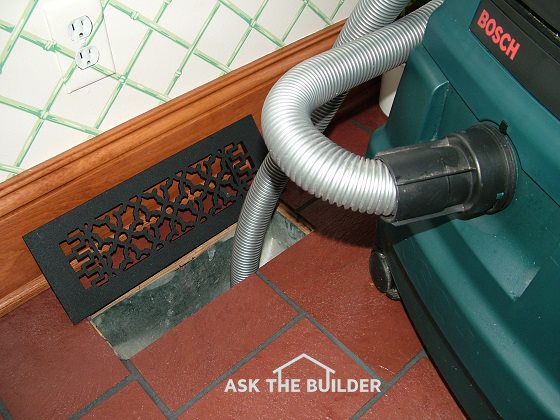

Here's an example of a giant return air grill near the floor. It's much better to put a return-air duct in each room.

What, you don't think you can match the hardwood flooring? Rubbish! Go to a first-floor closet and get the flooring from there. A good hardwood installer can make the repair and no one will be the wiser. Who cares if the flooring inside the closet doesn't match.

I wish you luck in your effort to stay cool. Don't hesitate to contact me if I can help. CLICK the Ask Tim navigation button at the top of this page.

Air Conditioning Sizing Considerations

Residential air conditioners, both central and window units, are like shoes. They come in various, different sizes. Buy the wrong shoe and you will be uncomfortable. It is no different with air conditioning.

Bigger Is NOT Better

So you really want your house cold. What are you going to do?

Buy a monster 5-ton central unit? That could be a mistake. If you put in a unit that is too powerful (produces too much cooling), it will short cycle.

It will turn on, blast out vast quantities of cool air, and then shut off. The result will be improper dehumidification. You will be cool and clammy.

The air conditioner needs to run for a sufficient time to squeeze out the humidity that has seeped into your house. You achieve the highest comfort when the air conditioner removes as much humidity as possible from your interior air.

How Are They Sized?

To properly size an air conditioner, one has to perform a heat gain calculation. In other words, you must determine how fast heat is getting into your house and what things inside the house are contributing to heat gain.

To perform the calculation, you need to know how much insulation is in your exterior walls, how much is in your attic, the size and type of glazing for each window, the type of construction of each window, extra special lights or cooking appliances that generate heat, compass direction that each wall of your house faces, etc.

In other words, you have to do some work to get the equipment sized right. Tables and charts have been around for years that convert these measurements into BTUs. Once you know how many BTUs your house is gaining, you can purchase the correct sized air conditioner.

When purchasing a unit, ask for these calculations! Don't just buy the same size unit you now have. Maybe it was not sized right. Maybe you have upgraded your windows or insulation. Maybe you added a small or mid-sized room addition or remodeled an attic space.

Replacing An Existing Unit - BEWARE!!

If you have an existing house that needs a new central AC unit, be careful! For you to achieve the published efficiency and performance that is sold to you by the salesperson, the interior coil housed in the furnace must be compatible and matched for size!

If it is not, the outdoor unit will struggle to keep your house cool. It is a question you must ask the installer. Make him/her prove to you that the interior coil will handle the outside unit.

Remember, the inside coil could have been wrong from the beginning! The original furnace contractor could have downsized one size to save money. The AC will work, but not as well as it should have!

This revised column was featured in the August 8, 2021 AsktheBuilder Newsletter.

Column B143

The reason dimmer switches get hot is fairly simple. Some dimmers get hotter than others because of their design.

The reason dimmer switches get hot is fairly simple. Some dimmers get hotter than others because of their design.