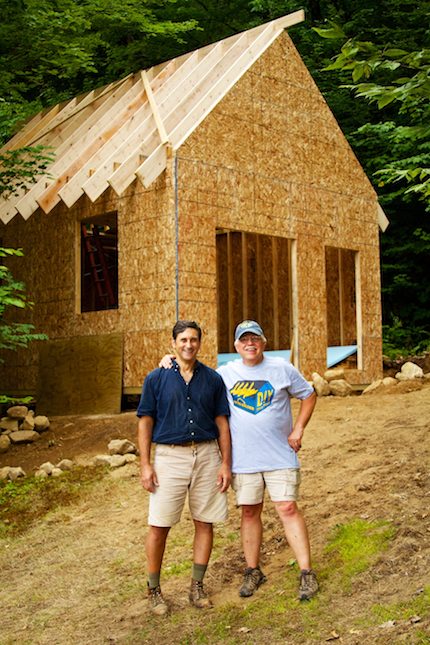

Building the new shed at my house has consumed me. That's why there was no newsletter last week. Tremendous progress has been made in a short amount of time. Check out the photo!

I'm standing with Robert Moore. He's an AsktheBuilder.com newsletter subscriber with extensive carpentry experience that came up from Towson, MD, to help me for nine days. The first day he was here, it was hot, humid, and all we had were eight piers staring at us along with eight very large holes in the ground that had to be filled in.

Robert's self-employed like I am. His day job is helping people with their PCs. He's a one-man geek squad! Don't let the Spartan appearance of his website fool you. He knows his stuff. Kathy and I discovered his Achilles Heel is ice cream - homemade chocolate ice cream made with hot custard.

The weather moderated and my good friends in Canada sent us some cooler weather! The cool air produced ideal working conditions with lower temperatures and less humidity. We only had one brief rain shower for 15 minutes that chased us away from the site in the first few days.

At the end of nine days, you can see what we got done. This week, if all goes well, I should have the roof complete.

Be sure to look at the bottom of this newsletter. I have a very fast Flash Sale on the entire set of videos that I'm creating. You do not want to miss out this time if you missed out when I launched the shed project on Kickstarter.

Tip of the Week - Ads and Mentions in This Newsletter

Have you ever wondered about bad or bogus products?

This is a reminder about product ads and write ups you see in this newsletter. I want you to know that I test and review just about everything I talk about. If I don't actually test it, I'll tell you.

But here's an example of what you don't see. A few weeks ago, I was approached by a company that wanted to buy ads in this newsletter. I asked about the product, and they told me it was a thing that saves money.

Look at the photo as it appears it's some sort of generator. It was some magical product that claimed to save you a huge amount of money on your electric bills. I actually think it's like the time machine in the movie Napoleon Dynamite. That was a funny scene indeed! Remember the crystals?

Here's a link to that funny movie scene.

My job is to vet stuff like this. I asked for a sample to be sent to me so I could test it. The company immediately stopped responding to me. They've not sent a unit to test, so that speaks volumes to me. Yesterday, I saw an ad for the exact product on a website I was visiting.

Simply put, I really value my integrity and will not accept advertising money unless I feel the products are of the highest quality. The products I mention here are ones I would use in my own home or on my own job site. Period.

I assume you want me to tell you about products that I would never use, right? If so, please REPLY to this newsletter and tell me.

Multi-Purpose Saw Tool

I received in the mail a Savage Folding Jab Saw / Utility Knife. It's a formidable weapon to have in your tool box.

When it's folded up, it's 7 inches long, so it's not going to fit in your pocket. This is why it comes with a soft-sided case that has a belt clip on it.

You can install, in seconds, any regular blade that you might put in a reciprocating saw. That's a big plus. The overall diameter of the tool is fairly substantial. I don't think it would fit well in a woman's hand, but I could be mistaken. The diameter is easily that of any framing hammer I've used.

All in all it's a fascinating tool as it gives you two tools in one. You've got a razor knife coupled with a jab saw that can be outfitted with blades to cut metal, wood or drywall.

This is a tool I'll use primarily for the jab saw function. It's just too big for me to use as my go-to razor knife. I LOVE my Stanley razor knife. I have several in case they ever think of discontinuing it!

Click the two links just below to see the Swanson tool and my absolute favorite razor knife.

DeWALT Saw Stand Video

Here's a video I taped a few days ago that you should like. If you've never seen this DeWALT miter saw stand, you'll be blown away.

Pocket Door Contest - Please HELP Pick the Winner!

We have our entries in the LE Johnson Pocket Door Contest!

Some are remarkable, and if you go look at the entries, you'll be treated to a video!

Click here to see them.

Please do me a favor and VOTE for a winner. It's easy to go through the entries. The link to the vote ballot is at the above page. Click that link just above.

Lumber Species

You may think that all framing lumber is the same. Framing lumber is that which is used to build floors, walls, and roofs. Trim lumber is the fancier lumber used for moldings, bookcases and other interior and exterior finish applications.

I believe to the average person framing lumber pretty much looks the same. However, if you look closely some of it is very different in color. Pick up two same sized pieces of lumber, but of different species, and you'll be stunned by the weight difference.

I was lucky enough to get the Southeastern Lumber Manufacturers Association to connect me with a New Hampshire lumber yard that stocked southern yellow pine (SYP). It's a fantastic lumber to use when framing.

If you compare it to other lumber, you'll quickly see how strong it is. It's also heavy. There's lots of dense summer wood in southern yellow pine. This contributes significantly to its weight.

Spend some time looking at span tables and you'll quickly see that SYP is almost as strong as Douglas Fir. I'm telling you this so that you know you have choices when building a structure. Some species of lumber are better suited for roof rafters and floor joists than others.

For more great information on wood, I urge you to visit the Real Outdoor Living website.

FLASH Video Sale

The sole purpose of my shed project was to create an authoritative step-by-step series of videos about building a shed.

I discovered after the fact it was a big mistake pitching the project that way. It's not about building a shed. It's about you saving Time and Money on any number of projects.

Maybe you just want to know how to install a door. Perhaps you want me to show you how to layout a wall. That's what all these videos are about. Hundreds and hundreds of tips. There are at least 30 different aspects or parts to the overall series. A partial list is just below. For the FULL list, just go here.

What I'm really creating is a collection of DIY videos that show you how to do any number of tasks. For example, would you like to know how to:

- layout a simple foundation

- excavate for a pier

- install a concrete pier

- frame a wood floor

- install asphalt shingles

- install an exterior door

- install a skylight

- etc.

You get the point. Watching all of these videos shows you how to build a shed. But just watch a few and you can see how to do one part of the project.

Here are two videos I taped while building the shed you can watch to see the kind of detail and teaching that's going on.

When this shed project was announced here in the newsletter a few months ago, you could have purchased the entire series of videos for $30. That opportunity is now gone.

But for the next few days, you can invest just $50 for the entire series. That's an insanely low price. Why? When all the videos are done, each *part* of the series will probably sell for $7-9 each.

Since there are 30 distinct aspects of the shed-building project, you can see that if you purchased each video series separately, you'd spend over $200. Multiply 30 times $7 or $9.

Watch this video that explains what's going on.

Just watching ONE of my videos could save you $50. Heck, the one video that shows you how to expertly square up the floor would save you that in headache pills!

Originally, I thought there would be about 100 videos in the entire set. I was wrong. There will be many more. How many? I don't know. I already have about 60 completed, and I've not even finished framing the roof!

Here's what's going to happen. Each week, the price of the entire video set is going to go up. If you want the current best price, you need to act now.

Next Monday, August 6th, the price will jump to $69. Each week after that the price will go up as I add more videos to the package.

Act NOW and you get all the videos I create about the shed for just $50.

This sale ends on Sunday, August 5th, at midnight ET. Make sure you're one that gets the entire series for the $50 price. I can't ever imagine the price being lower. Invest in the series NOW to get this huge value that will save you time and money.

If you decide to make this investment, realize that you'll not get access to the videos until the project is COMPLETE. I envision you'll get access to the videos late in September. You need to be patient. I'll get the videos to you, but you need to let me finish the shed first. I can't create a video until I do the job, right?

Right now I'm too busy building the shed to help edit the videos and write the comments that accompany them.

I have two reasons, one named Clara and one named Evelyn. Sure, they look sweet, but they're trouble. The older one (2) likes to open and close doors, often when the younger one (9 months) is in the path of the door swing. Putting pocket doors in the most frequented areas of the house will save untold amounts of money in ER bills. It will probably save my sanity, too, or whatever is left of it.

I have two reasons, one named Clara and one named Evelyn. Sure, they look sweet, but they're trouble. The older one (2) likes to open and close doors, often when the younger one (9 months) is in the path of the door swing. Putting pocket doors in the most frequented areas of the house will save untold amounts of money in ER bills. It will probably save my sanity, too, or whatever is left of it.