What's in This Newsletter?

Lastest News

Termites and Water

Past Newsletters

Facebook Fun

Snow Dragons

Toilet Wax Gaskets

Water Pressure Booster Pump

Remember, Do it Right, Not Over!

I do product reviews frequently. Please read my Disclosure Policy to understand the relationship between me and the companies that make the products or offer the services I review.

FOLLOW ME ON TWITTER

Friendly Question Reminder!

If you have a question for me, don't hit the Reply button just yet. Go immediately to my web site and type in the keywords about your problem into my Search engine. The search box is at the top of every page of my web site. You could have your answer in seconds if you do this! Please pay attention to all links you see at my web site. The exact products and services you often need are right in front of you, and you might be ignoring them.

Latest News

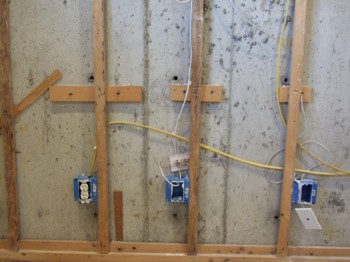

Oh how time flies. I'm swamped on the kitchen remodeling project here at my own home. It's fun but it's frustrating. I was to have a helper, but that person got tied up on another project. Lot's of dust here and I'm almost over the hardest part.

But what I wanted to share was something that happened to me when dealing with one of my suppliers. Yes, even I can get into a tussle about money. You would think I'm immune to that. Well, such is not the case. It's not a large sum, but it was the principal of the issue. I didn't want to pay for something that wasn't my fault.

There's no need to share the details of what happened, but I can tell you that the reason it's going to work out just fine is that I did follow all the advice I've given others for years: Put it in writing. You're thinking contract right? Well, you don't normally sign a contract to buy certain items.

In this case, the fact that my free Gmail email account SAVES every email, and that of my wife, allowed us to show the supplier where the communication problem broke down. You may use some other email program or online web-based email. No matter. The point is, don't delete emails. Gmail archives all of them automatically. Others I'm sure do the same.

Once we went back into our email archives, we were able to prove that we were NOT at fault. The emails clearly showed who dropped the ball.

This is the problem with doing business on the phone. You have no recording of what was said. If you do business like this, after you hang up the phone I urge you to do a quick summary of the key talking points. Put them in an email and send it to the person you're ordering from or doing business with. Ask them to reply to the email so you can prove they got it.

The emails that Gmail saved for us are going to buy a month's worth of propane. Thank you Google!

Termites and Water

Moe M. sent me a tip about termites. Here's what he said:

Moe M. sent me a tip about termites. Here's what he said:

I just want to share with you one quick point which may be of interest to your subscribers. My in-laws had a leaky pipe basement (occasional small leak) and they never got around to do anything about it. Boy were they in for a surprise when termites came flocking in, moisture basement seem to be great locations for termites to set up shop.

True indeed, Moe! Termites really need moisture. I have quite a few past columns about termites. Know that the little worker termites constantly are foraging for food. They do this non-stop. They also try to supply the colony with different sources of food. They don't like to put all their eggs in one basket.

PAST Newsletters!!

You may go to the trouble to archive my past AsktheBuilder newsletters in your computer. Know that I do the same at my website. Also realize that the enormously powerful search engine at my site can really help you if you know that I mentioned something and you can't find it in your archives. Just type in a keyword or a phrase and see if my engine finds it faster for you.

You may go to the trouble to archive my past AsktheBuilder newsletters in your computer. Know that I do the same at my website. Also realize that the enormously powerful search engine at my site can really help you if you know that I mentioned something and you can't find it in your archives. Just type in a keyword or a phrase and see if my engine finds it faster for you.

Facebook FUN!

Do you use Facebook? I can see why it's SO popular. A month ago, I launched an AsktheBuilder Fan Page. It's been great fun.

Do you use Facebook? I can see why it's SO popular. A month ago, I launched an AsktheBuilder Fan Page. It's been great fun.

Here's what you missed the past few days by not being a fan. I took a photo of a problem here at my house. I then asked the fans to comment how they would fix the problem. My plan was to see if someone had a better way! You should have seen all the responses.

I plan to do that as often as possible. Go check this out. Heck, if you don't have a Facebook account - it's FREE - this may be the thing to get you going.

www.facebook.com/askthebuilder

Snow Dragons

Last issue of the newsletter, I lamented about the crazy Medieval knights who slaughter the last dragons causing them to go extinct. I need a pet dragon up here in New Hampshire to melt the snow on my roof.

Marty Hovey, a great friend of mine and one of the original subscribers to this newsletter sent me a link to a modern snow dragon!

Toilet Wax Gaskets

Helen Harris of Taneytown MD emailed me:

My granddaughter's husband put new wax seal on toilet. Problem - he flushed the old sticky seal down the toilet and we think that is what is causing the toilet to now clog up. We used a snake and it came back with some of that waxy stuff on the end. After snaking, it was okay for a few days then clogged back up again. Is there something that will dissolve it or flush the remainder away? I don't know if it is hung up in the pipe or what and the toilet paper adheres to it and that's how it is clogging or what. Any ideas or suggestions are greatly appreciated.

Helen, what a problem. I don't know of anything that would readily dissolve that wax. That would be very problematic as if a person used that with any frequency in a toilet, it would break the seal. I'm afraid you'll have to just continue to rod out the pipe.

Never ever put something sticky like that down a drain pipe. I'm sure he knows that now.

Water Pressure Booster Pump

If you could read my daily email, here's what your executive summary would be:

Tim, the people that email you just want the Easy Button. They are busy and just want the products and services you use personally. If it's good enough for you, then it's got to be great for them.

You know what? That's exactly the common thread in most of the email I get. You just want me to tell you what to buy or who to hire.

To that point, I made a decision over the past two years to go out and find what I feel are the BEST products out there. The ones that really work. I have problems of my own at my home and don't want failures.

This is why I found the best gutter guards. This is why I did the research and found the best water conditioning system, or what I feel is the best.

This home I bought here in New Hampshire is on a well. The well pump only produces 50 pounds of water pressure. That pressure drops to 30 pounds before the well pump comes on. It's dismal pressure, especially when you realize I came from a house in Cincinnati, OH that had 90 psi. That was just over the recommended limit, but I never had issues with any of the fixtures.

So on my list of things to find was a fantastic water pressure booster pump. It's a long story, but last summer the owner of a great Yankee New Hampshire manufacturing company called me. I got to meet Ned and his team back in November of last year while visiting his facility.

He showed me these gorgeous variable-speed booster pumps that were to be used on large buildings, college dorms, and restaurants. Places that needed reliable water pressure all the time.

I discovered there are vast differences between pumps. The variable speed one is quieter and does a superior job than some of the cheaper ones on the market.

I blurted out, "Wow, do you make smaller ones for a residential house that will take my pain away?" Ned grinned and walked me over to a shelf that had this pre-built system ready to go. I believe he said, "Tim, this little pump will deliver 80 psi at 10 gallons per minute till the cows come home. This assumes you have enough water coming into your home to supply the pump. I can't make water that's not there."

I've been a master plumber for over 25 years. I could see the pump could be installed with no problems. It was just like hooking up a new electric water heater. One water line in, one water line out and connect an electric cable.

The entire pump, expansion tank and all-important electronic pressure regulator is all mounted pre-wired and connected on a painted steel frame. You just set it in place, pipe it and wire it. It's unbelievable.

Ned was quick to point out that some of the smaller 120 volt pumps you just plug into an existing outlet that's on it's own circuit. In other words, they are SIMPLE to install. I went for a 240-volt model that required it to be hard wire it into my electric panel. That was easy to do.

Three weeks ago, I had one installed here at my New Hampshire house. The entire job took less than two hours. The moment the pump was turned on, I had incredible pressure. WOO HOO!!! I'm one happy camper as is Kathy. I'm going to tape a video showing my pump as soon as I get past this kitchen job.

So here's the bottom line. Ned wanted to buy advertising on my website. I said No. I've decided to do it a different way. Since you just want me to tell you what I use, then I'll just get compensated IF you decide to take action. So Ned and I worked out a deal where I get a tiny commission if you buy a pump like mine. It's a win-win-win.

At the end of the day, you win because you get a great product made here in the good ole' USA! Ned and his workers win as well. I win because I can start to reinvest the commission money to grow my team to help find even MORE products you want.

You can go to Ned's website, but I URGE you to call them. Make sure you tell them you heard about him from me. You can order directly online if you want, but it's best for them to ask some questions so they can absolutely make sure you get the right pump. Ned and I want to make sure the pump is going to work perfectly in your home.

Go to Ned's website and tell me what you think. He's got a great installation guide if you want to do it yourself. If you want to hire a pro, it should take about two hours. That's not bad!

AsktheBuilder.com

100 Swain Rd.

Meredith, NH 03253, USA

I'd like to talk to the idiot medieval knights who slayed the last dragons. We've had a constant flow of storms here in the Northeast and although I LOVE the beauty of the snow, I'm growing tired of raking it off the roof here and dealing with it near my front door.

I'd like to talk to the idiot medieval knights who slayed the last dragons. We've had a constant flow of storms here in the Northeast and although I LOVE the beauty of the snow, I'm growing tired of raking it off the roof here and dealing with it near my front door.

I was wondering for those who live within driving distance to central New Hampshire if you'd want to have a sleepover meet up? You and your significant other would rent a room for one night - you could stay the entire weekend if you want - at the Atwood Inn. Wait till you see their new website and the videos of all the rooms!! Go watch the video for the White Mountain Room, but be sure to watch the video first on the home page for it to make sense.

I was wondering for those who live within driving distance to central New Hampshire if you'd want to have a sleepover meet up? You and your significant other would rent a room for one night - you could stay the entire weekend if you want - at the Atwood Inn. Wait till you see their new website and the videos of all the rooms!! Go watch the video for the White Mountain Room, but be sure to watch the video first on the home page for it to make sense.