Different Construction Quality Levels | I finished this Sun Room for my wife not too long ago. In this photo, it looks wonderful. You would probably think so if you were standing in the room. But there are no less than 20 small defects that some anal retentive people would freak out over.

DEAR TIM: My six month old concrete driveway is crumbling. The contractor visited and said I got what I paid for. Believe it or not, he said my house wasn't a "million dollar house" and he did not do as good a job on my drive as he might elsewhere. Is that fair? That answer seems totally unacceptable to me. Shouldn't the highest level of quality be done on every job no matter how much a house is worth or what the homeowner's income might be? Lori J., Cincinnati, OH

DEAR LORI: You have just lifted up a rock in the stream that I feel has laid untouched for too many years. The subject of quality in residential workmanship as well as materials used to build and remodel homes is one, in my opinion, that has not been addressed head on. It is a highly sensitive issue and undoubtedly will spark heated debate between all who have a skin in the game.

Are there different levels of quality in a remodeling project?

The quality problem is a tough issue to discuss because it is simply so subjective. Two people will have two entirely different opinions as to the quality of an item. I have worked for some people who are obsessive compulsive perfectionists. Many of these people expect absolute perfection from others, especially those to whom they are exchanging money for services, but they can't produce a perfection in the work they do. This is a classic example of the double standard. Other people I have worked for were as happy as clams and willingly accepted drywall that may have a few minor nail pops or seams that show in a certain type of light. Note, I am not saying this was acceptable workmanship, I am saying the customer found it to be so.

Quality is also a mind set issue from the perspective of the consumer. Visit a grocery or dry goods store and you often will see similar products that are in different cans. Take tomato paste or paint for example. What can be so different about these? Well, maybe certain tomatoes that are the best have a far less yield per acre than commodity tomatoes. Maybe the higher priced tomato paste has very special expensive spices in it. Paint, although it looks the same once the lid is popped open, can have vastly different ingredients -some of which cost far more money than others.

But many consumers readily accept these things and make decisions based on price, taste, performance, etc. when they buy these types of things. This thinking seems to fly out the window when they hire a contractor. There seems to be only one level of quality and it is a high one. If a contractor doesn't hit it, then he seems to be guilty of some infraction.

Can all contractors do the highest quality work?

The truth be told I believe each person should do the best job they can do every time they work. Therein lies the conundrum: Not everyone can do the highest quality work! Well, they can, but what is great work to them may be totally unacceptable to you. Some people do not possess the skill sets, hand-eye coordination and/or the training and experience to deliver work that is perfect or nearly so.

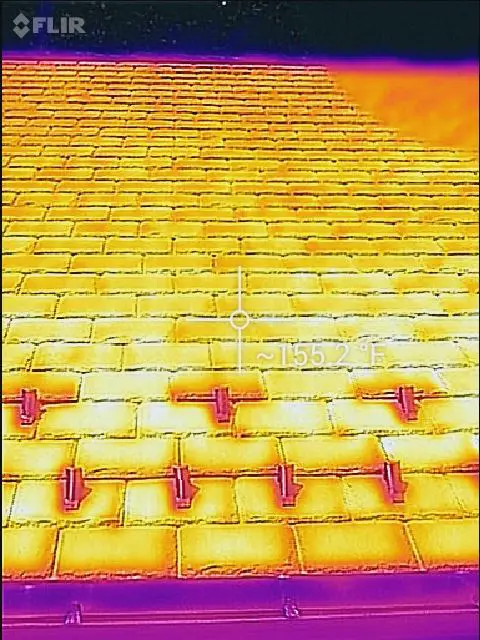

Add to this the fact that some building materials do not tolerate poor workmanship very well. Concrete happens to be one of these. There are very strict industry guidelines as to how concrete should be specified, ordered, installed, finished, etc. to get long-lasting results. Your driveway should not be falling apart. My guess is that an autopsy would definitively show a workmanship error or errors. Odds are your driveway will have to be replaced.

How would you like me to build your new home? It's probably impossible for me to fit your job into my schedule, but I will gladly share hundreds of my tricks and building secrets with you and your builder. Check out my New House Specifications.

Some poor workmanship can be easily fixed, but not all.

Sometimes mistakes or poor workmanship can be easily rectified. Take the case of drywall. A rookie finisher can mess up a wall or ceiling horribly and I or another experienced finisher can come in and make the surface look as smooth as silk in one day or less. The sheets of drywall do not need to be replaced; inexpensive topping compound just needs to be added and sanded.

There are several ways to fulfill your expectations on all future jobs. Contractors can possibly start to do what other companies do. I suggest they consider offering customers a variety of finish levels with corresponding prices. These finish levels would have to be clearly described or physical examples would have to be developed that matched the final product. If you can get by with a granite top that has some imperfections and the seams aren't perfect, then maybe you pay X dollars. If you want perfection, then you pay Y dollars as the fabricator decides they will have to spend many more hours measuring, fitting, polishing, etc.

Search the internet for associations that have written specifications and installation instructions

You, as the consumer, can start to do a better job of defining exactly what you want done and then finding the contractor that can indeed fulfill your expectations. There are many associations that have thousands of written pages of specifications and installation instructions that can help you form written specifications. Don't depend upon the wording of the contractor in the contract. Include language in contracts that references specific written installation instructions provided by all manufacturers. These are very easy to obtain via the Internet.

CLICK or TAP HERE to get FREE quotes from local contractors to tackle your project.

Finally, take the time to find real professionals who already strive for perfection. Rest assured they are out there. They live in just about every city or town. These pros have a passion for their vocation. They use the best materials and spend the time on the job so they don't have to make a return visit to redo work. But the trouble is, their price is *not* always the most expensive one. It boils down to homework: lots of homework on your part to write the job description and then find a person who can prove to you they can do it.

Caveat emptor was the standard we were all held to until the recent wave of consumer law brought the scales of justice into a little better balance. Each party to a contract needs to work in good faith to fulfill the terms of the contract and in some instances they do. But the problem is, the contract may not have contained definitive enough language or terms that allow an independent third party to make a decision as to whether or not the terms of the contract have been fulfilled.

Surprisingly it is not as hard as you might think to write a crisp set of specifications that allow you to find a professional. Some of these specifications and forms are actually for sale on the Internet. Others can be obtained for free from manufacturers' associations or the actual product manufacturer. You simply have to incorporate the language into your set of bidding specifications, plans and/or the final contract between you and your contractor.