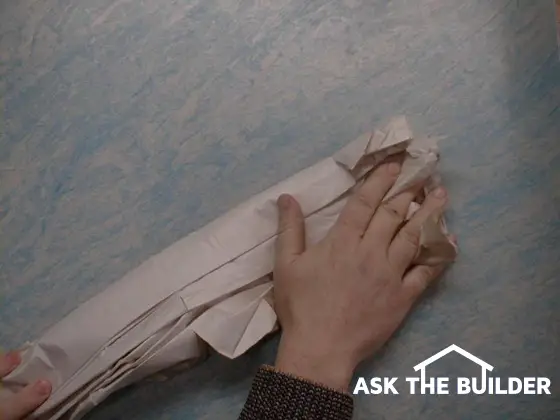

There is a one-half inch thick layer of ice on my front sidewalk paving brick. I sprinkled some magnesium chloride pellets on it and they started to work within seconds. You can still see a few of them up at the surface.

DEAR TIM: Ice and snow cause big problems where I live. My sidewalks, driveway and concrete and wood steps get slippery. Is it safe to use deicing salts on concrete, asphalt and wood surfaces? I have been told that deicing salts can cause severe damage to concrete. Are there safer salts that work differently than others? What about using fertilizer as a deicer and traction aid? Jenny L., Lewiston, ME

DEAR JENNY: Deicing salts can cause severe damage to concrete that has not been formulated, mixed, installed and finished properly. That is a fact. The good news is that it is easy to install concrete so that deicing salts can be used with confidence knowing that little or no damage will occur over the years. If you come to my city, I can show you city sidewalks and roadways that have had repeated treatments of deicing salts for years. These strong concrete surfaces have experienced none of the spalling or surface erosion that you have heard about.

The damage to concrete most people fear is actually caused by the freezing and thawing of water that soaks into the upper surface of the concrete. The use of deicing salts increases the amount of freeze-thaw cycles that a concrete sidewalk or driveway experiences. The volume of water increases by 9 percent when it freezes. This expansion creates internal pressures that can blast apart weak concrete.

Concrete that contains small air bubbles (air entrained), a minimum of 564 pounds of cement (6 bag mix) per cubic yard and a minimum amount of water when mixed (4 inch slump) can resist repeated episodes of ice expansion within the concrete. In addition, the concrete must be moist cured at or above 50 F for a minimum of seven days, produce a 28 day strength of 4,000 pounds per square inch and have a minimum drying time of 30 days before it is subjected to the first freeze-thaw cycle. These practices are commonly followed by experienced, professional concrete masons.

Deicing salts rarely cause problems on wood surfaces and asphalt. What little damage they may cause is far outweighed by the benefits of preventing personal injury as a result of a fall on some ice.

There are four primary deicing salts. All have different characteristics. The most common deicing salt is regular rock salt or sodium chloride. It is widely available and can melt snow and ice until the temperature drops to between 16 and 20 F. Below these temperatures the rock salt stops melting snow and ice. Rock salt also releases the highest amount of chloride ions when it dissolves. Chloride can pollute streams, rivers and lakes. The chloride also causes metal to corrode.

Get a 24-page guide right now that answers all your questions about Deicing Salts. Will it RUIN your concrete? Did you know that salt can SERIOUSLY harm you? What about your expensive landscaping? You can have all these answers and more in less than a minute. Buy it NOW. Get a 24-page guide right now that answers all your questions about Deicing Salts. Will it RUIN your concrete? Did you know that salt can SERIOUSLY harm you? What about your expensive landscaping? You can have all these answers and more in less than a minute. Buy it NOW. |

Calcium chloride is another deicing salt. Many people have seen these small rounded white pellets. It can continue to melt snow and ice as temperatures fall well below 0 F. It can cause skin irritation if your hands are moist when using it. Concentrations of calcium chloride can chemically attack concrete.

Potassium chloride is a deicing salt that available in some markets. It is not a skin irritant and does not harm vegetation. It only melts ice when the air temperature is above 15 F, but when combined with other chemicals it can melt ice at lower temperatures.

The newest deicing salt is magnesium chloride. It continues to melt snow and ice until the temperature reaches -13 F. In the photo, the air temperature was 0 F. The magnesium chloride melted through a 1/2 inch thick layer of ice in just 10 minutes. This salt releases about 40 percent less chlorides into the environment than either rock salt or calcium chloride. It is also less damaging to concrete surfaces of questionable or unknown quality. Magnesium chloride is less toxic to plants, trees and shrubs (see Author's Note at the bottom of this column). It also does not leave a powder residue when tracked into your home.

Avoid the use of fertilizers as deicing and traction agents. Those that contain ammonium nitrate and ammonium sulfate can rapidly disintegrate concrete. Don't take a chance if you don't know what is in the fertilizer. If you don't have salts available use sand to stop you from slipping and sliding.

Author's Note: In 2001, the USDA published an article entitled "Magnesium Chloride as a De-Icing Agent" that stated magnesium chloride led to "corrosion of steel and aluminum poles and pole hardware." Although used as an effective deicer, updated evidence after the publishing of this article on AsktheBuilder.com shows it can lead to harm of electric utilities. The article can be read here.

Also, a February 2003, Board of Montana Flathead County Commissioners minutes document called "Magnesium Chloride on Roads" on Corrosion-Doctors.org attests to magnesium chloride's corrosiveness on aluminum and steel. In a corrosion comparison done by Colorado D.O.T. and the University of Colorado, it was found that "road salt is more corrosive to the metals than mag chloride on a one time exposure." However, magnesium chloride corrodes over longer periods of time, and Greg Fulton, president of the Colorado Motor Carriers Association, said it corroded aluminum on his vehicles as well as led to wiring failure. This document can be read here.

Related Articles: Deicing Facts, Guidelines for Strong Concrete, Magnesium Chloride & Deicing Salt Companies

Column 251