DEAR TIM: I want to install ceramic tile on a concrete floor under a free-standing fireplace and on the drywall behind the fireplace. I live in a colder climate and the floor is very cold to the touch. Can I successfully install the floor and wall tiles if the surfaces are cold to the touch? If so, how? I have fears of the tiles popping loose and falling down one-by-one over time. Rhonda S., Manitowoc WI

DEAR RHONDA: To set your mind at ease right away, you can easily and successfully adhere the tiles to the floor and wall surfaces if they are above 45 F. Concrete and wall surfaces can often feel very cold but believe it or not, the actual surface temperature is well above 45 F. There are bigger issues, however. You must use the correct adhesives to make sure the tiles stay put and will not crack. What's more, there may be serious building code issues involved with respect to the distance the fireplace is away from the wall.

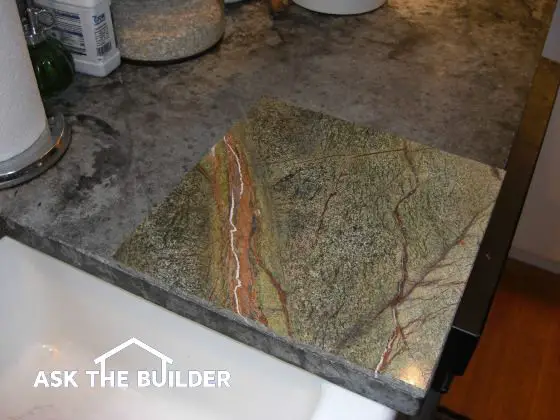

These two different ceramic tiles are installed over two separate layers of plywood. The total thickness of the plywood is 1 and 1/4 inches.

The first thing I would do is consult with the building department officials in your town to make sure you have the necessary fire and heat protection in place. I realize you have drywall in place right now on the wall, but it may be prudent to attach an additional sheet of fireproof one-half inch thick cement board over the drywall immediately behind the area you plan to install the tile.

Doing this will create a minor finishing detail problem as the edge of the cement board will be clearly visible. But you may be able to hide this edge with trim ceramic tiles or a decorative wood strip. If you decide to use wood, be sure that the code permits this as wood is a combustible material. Often there are minimum distances that combustible materials must be placed from wood stoves.

The concrete floor is an excellent substrate for your floor tile. I would use cement-based thinset as the adhesive for the floor tile. This product is readily available at many tile stores. Once mixed with water, the thinset has the look and feel of brick mortar. It is often available in gray or white color. Another advantage of using thinset is that it dries rock hard. This is very important as the legs of the free-standing fireplace will create a concentrated downward force on the fragile tile. If you were to use the organic adhesives that look like cake icing, the tiles could crack. The organic mastics do not dry as hard as the thinset.

If you're putting ceramic tile in your home, check out my Ceramic Tile Installation Checklist to learn exactly what you should know about the process. Avoid making costly mistakes with the help of this document. I offer a 100% Money Back Guarantee.

The cool concrete surfaces are actually ideal to work on. This temperature slows the set time of the thinset. Hot surfaces speed thinset setting time. In fact, if a surface is too hot, the thinset may skin over or partially dry before you have a chance to set the tile. If you feel the surfaces are too cold to work upon, simply use a space heater that can temporarily heat the surfaces slightly before you are ready to install the tiles.

Once the tiles are in place, you can then operate the space heater once more to keep the tile, thinset and concrete/cement surfaces between 45 and 70 F for a period of 12 hours. This is plenty of time for the thinset to activate and bond the tiles to the cement surfaces.

Be sure the concrete and cement board surfaces are sound, dust-free and slightly damp before you spread the thinset. Doing this will insure the highest level of bonding. I also recommend that you precut as many tiles pieces as possible before you start. Once the thinset is mixed and spread out, you want to place the tile within 10 to 15 minutes. If you wait much longer, the thinset loses its ability to create a permanent bond.

Column 438