How are you today? I think you could be a new subscriber! I devote this top paragraph to you. It’s always a pleasure to meet a new subscriber.

On the other hand, you very likely could be a subscriber who’s like a fine wine, getting better with each issue. You’ve been with me so long there could be a layer of dust on your first issue dating back from all those years ago.

Some people dust every other week out of force of habit, and if you’re one, you might try an electric leaf blower for the task. It’s so fast!

CLICK or TAP HERE to see one I’ve used to remove dust from things. I’m telling you, don’t discount using one around or in your home. Inside, be sure to use an electric one.

Pro Dusting Tips: Be sure to use strong adhesive tape to secure irreplaceable family photos on your mantle or walls when directing the blower air at them. Turn on the whole-house fan and open key windows to suck all dust up into the attic and out of your house.

Pumpkin Carving Saw

If you had to carve a pumpkin in less than two minutes, do you think you could do it? I did it two nights ago!

CLICK or TAP HERE to see how fast I did it. Ignore the items on the island! Nothing to see there.

Exploding Alkaline Batteries!

Alan lives in Rochelle Park, NJ, and sent me an urgent communique’ this past week.

He was replacing a triple-A battery in a bicycle light when in another room an older AAA alkaline battery EXPLODED.

Alan said, “The battery had been sitting on a table on the first floor for about a week. I was upstairs and my wife was on her computer about 9 feet away from the battery when it blew up. We have no idea what triggered it.”

Let this be a warning to you. Dispose of old batteries properly and keep them away from any flammable materials. Punch some large air holes in a closed metal container where you intend to place the old batteries. These holes allow explosive forces to hopefully prevent the lid from blasting into the stratosphere. Store the batteries outdoors in case they explode before you can get them to the recycling center.

Noisy Neighbors in Apartment Building

Mary reached out to me days ago. She hails from Rockfall, CT, and had this great question, “What are the absolute BEST blown-in soundproofing materials for an apartment wall that I share with my neighbor? It's just a sheetrock wall. This is HUD housing and the management company here is willing to do this. I will also contribute to the cost to help save my sanity. Any other ideas would be very much welcomed. I trust your judgment and I love your column in the Hartford Courant!”

Let’s start with Mary’s last comment about my syndicated newspaper column. Do you read my column in your local paper? If so here’s a Pro Tip.

My guess is you might like several features in your local or online newspaper. If so, you should periodically write a pithy letter to the editor sharing with her/him WHY you like the feature. Give some examples of how it’s made you laugh, allowed you to make the perfect cake, or in my instance, perhaps I saved you a boatload of money and time.

Editors NEED periodic positive feedback from readers. Without this, they could start to think NO ONE likes a feature.

They’ll cancel it, replacing it with something else and believe me, it’s next to impossible to get them to change their minds. Understand, in my case, lots of editors get negative comments from contractors or manufacturers I call out in my columns. So I need your help to keep my column in your paper.

Now back to Mary’s issue with her sound problem. Sound is transmitted through the air as soon as something starts to vibrate. Thick dense walls and floors in older homes are harder to get to vibrate than thin crap walls in newer apartment buildings and condos.

CLICK or TAP HERE to get a feel about how to make things soundproof in your home. It can be done to an existing home, apartment, or condo with some effort. You need to think of your room or house as a ship at sea! This will make sense once you read the above column.

Granite Cobblestones - Great Edging

Here’s a photo of granite cobblestone edging next to the tar and chip driveway at my previous home in Cincinnati, Ohio. CLICK or TAP HERE to see amazing photos and a VIDEO of how this colored driveway was installed.

Did you know you can often purchase salvaged granite cobblestones? If those aren’t available, you can most certainly obtain new ones.

Granite cobblestones can have an interesting history. I cover that in this column you should peer at. You might be able to get granite that was harvested in Europe of all places!

CLICK or TAP HERE to watch a video about how easy it is to install granite cobblestones at your home.

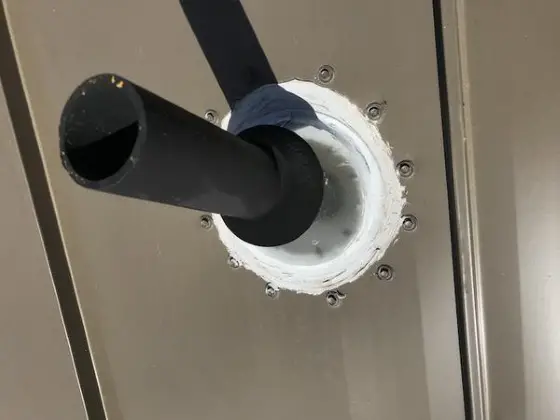

Installing Flashings on Metal Roofs

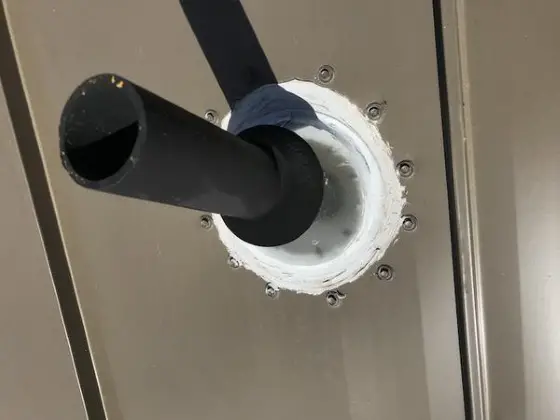

Ken, who lives in sunny and on-fire California, did an extensive phone consult call with me several days ago. He had a metal roof installed on his house a few years ago and has been wringing his hands about all of the flashings that surround pipes and vents poking up through the roof.

The installers smeared a bunch of caulk around them like this:

Can you see what’s wrong with this installation technique? How do feathers on a bird work? Have you engaged your God-given critical-thinking skills as to how asphalt shingles work with gravity to keep you dry?

You do know that caulking is NOT a permanent roofing material, right? The sun's ultraviolet light destroys caulk as you might crush an oyster cracker in your hand.

Do you have a clue how tinsmiths installed flashings 150 years ago with NO CAULK? Would you like to see how they did it?

I thought so. Ken asked me to make a video for him so he can do the roof repair himself saving thousands of dollars. Would you believe he was quoted $5,000.00 to do the work? I feel Ken could most likely accomplish modifying the flashings in about eight hours. If so, the money Ken invested in the phone consult and the video creation is going to pay off in spades.

Since I don’t have a metal roof with GOOFED-UP flashings to fix, I decided to make a model for the video using a paper cup and some old file folders.

CLICK or TAP HERE and you’ll be amazed at how SMART those old tinsmiths were!

You need to understand I’ve installed lots of flashings in metal roofs for decades using this method and I’ve never had a leak.

That’s quite enough for a Sunday.

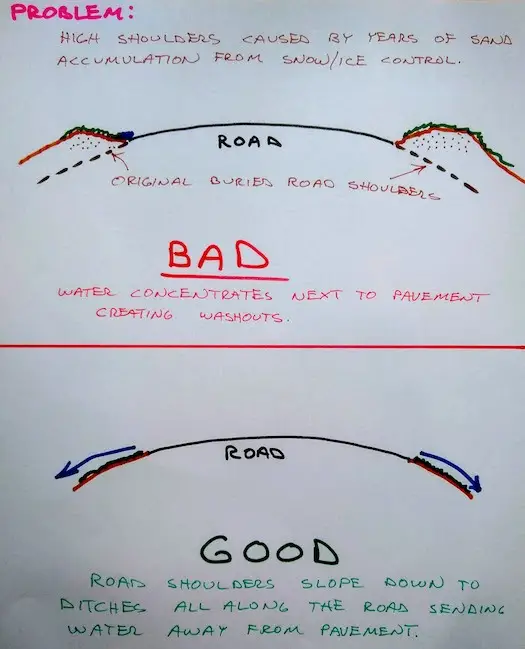

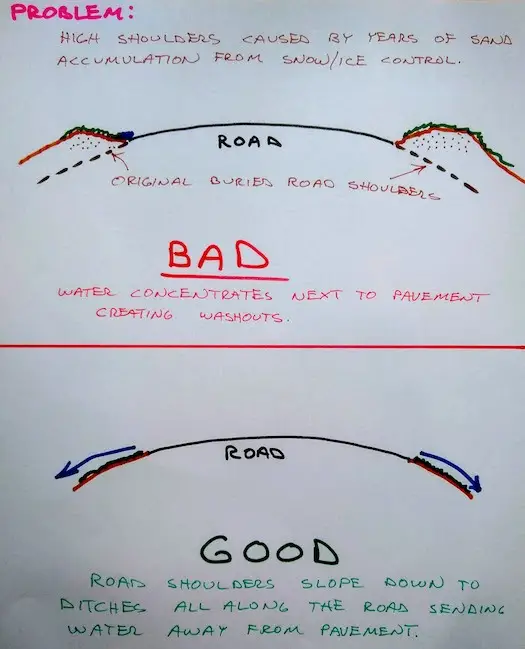

Oh, one more thing. After church today, I’m going on a walk down my street with Tamara. She’s a neighbor and board member of my association. She wants me to explain why all of a sudden we’re getting washouts along the pavement.

So simple! I made this fast drawing for Tamara to share with the other board members. You do know that roads have crowns. Why of course you knew that!

Tim Carter

Founder - www.AsktheBuilder.com

Best Darn Cleaner - www.StainSolver.com

Solved South Arm! - www.W3ATB.com

Do It Right, Not Over!

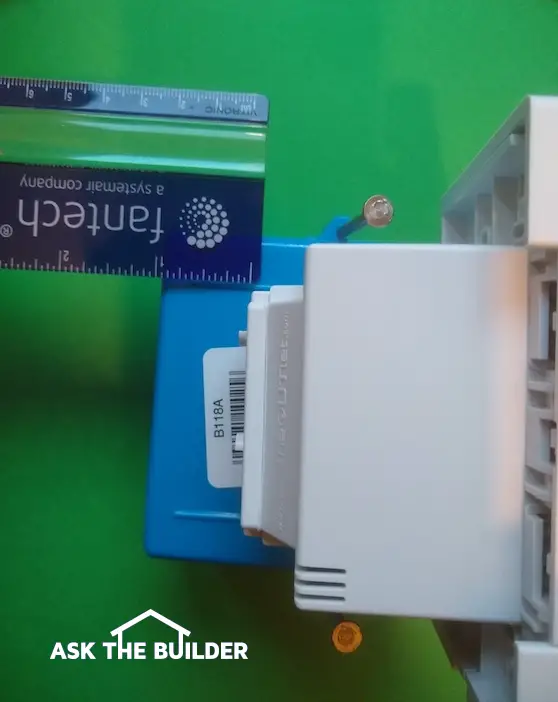

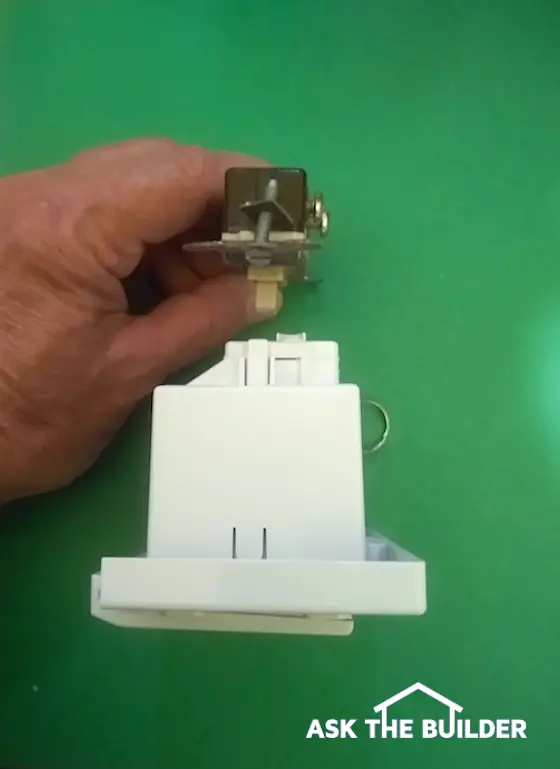

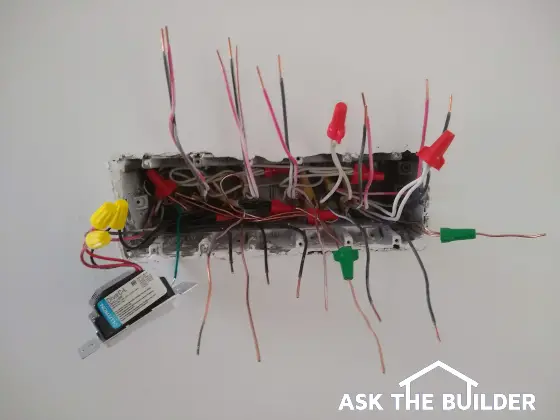

P.S. How do I stay warm in my cave above my FREEZING COLD garage all winter? I thought you’d never ask. CLICK or TAP HERE and watch the short videos.