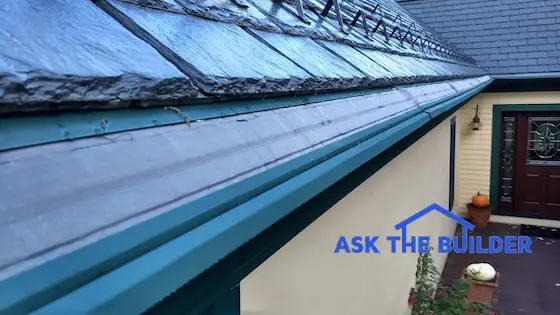

Here's Dave's foyer floor sans ceramic tile. The concrete mortar looks horrible, but it's an excellent base for laminate flooring. All it needs is a thin layer of pourable self-leveling compound. CLICK THE IMAGE TO ORDER SOME NOW. © 2017 Tim Carter

Laminate Floor Over Concrete TIPS

- Laminate floors must be on solid and smooth floors

- WATCH my Laminate Floor Video Series BELOW!

- Concrete is a solid base and excellent

- Use self-leveling compounds to make concrete smooth and level

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: I’m renovating a 1969 ranch home that’s over a crawl space. I pulled up the existing foyer tile floor so I can put down an interlocking laminate or engineered flooring. Much to my surprise I found a concrete mortar bed under the tile. I'm assuming the mortar must be removed and I add more wood sub-flooring on top of the existing plywood subfloor. Is that a correct assumption? The mortar sits, on average, about 1 inch below the existing finished floors. What would you do at this point? How would you deal with this wretched concrete mess? Dave H., Charlotte, NC

DEAR DAVE: What’s that old saying? “One man’s trash is another man’s treasure.” Yeah, that’s it. My friend, you’ve been blessed is all I can say. I suggest you prance around your house singing Happy Days are Here Again.

That concrete mortar floor is an excellent base for your new laminate floor once you dress it up.

True Sad Story

Allow me to share a story. A friend of mine purchased an older home in the town where I live. She and her boyfriend embarked on doing lots of remodeling to this tired, old one-bedroom home.

One of the last projects they tackled was installing a laminate floor. This woman knows that I have a little bit of knowledge about matters of home construction and remodeling, yet she didn’t call me up. I think it might have had something to do with offending her boyfriend’s skills. It’s too bad that as most people get older, their egos get more fragile, but that’s a story for another day.

I don’t know if they didn’t read and understand the laminate flooring instructions, were in a rush, were too tired at the end of the job or thought they knew better, but they made a grievous error.

Interlocking laminate flooring materials are very interesting products. I put down one in my man cave ham-radio shack about three years ago that looks like random-width v-groove distressed oak flooring. Everyone that’s seen it thinks that it’s real oak and that the floor is perhaps fifty, or more, years old. It looks that good.

But I read the installation instructions and they say the flooring must be installed on a solid floor that’s all in the same plane. This means the sub-flooring shouldn’t move or flex and that it must be smooth with no humps or low spots. If you don’t satisfy these basic requirements, the laminate flooring will snap, crackle and pop as you walk across it.

My friend made this mistake and her floor creaks and snaps as she walks across it. She called me a month after the install asking me if there was a way to repair it. I told her she might be able to inject a material, with great effort, under the floor in the worst spots, but that the best way was to disassemble the floor, get the subfloor in the same plane, and re-install the flooring. She chose not to do that.

Step One Complete!

How does all this relate to you? Simple. That concrete mortar floor is nearly as solid as the Rock of Gibraltar. I’m pretty certain a month ago before you started the demolition when you walked across that tile foyer floor you felt like you were on bedrock. That satisfies the first requirement for a laminate floor. Your subfloor is solid with no flex.

The issue you have now is the concrete is not in the same plane. The concrete mortar is uneven, it’s gross and it’s well below the level of the existing floors in the adjacent rooms. That’s easy to fix with a self-leveling pourable floor compound.

This is a powder you mix with water. You then pour it and it levels itself. It's magic. CLICK THE IMAGE NOW TO ORDER IT.

Radiant Floor Heat Pad? - Do It NOW!

You have a unique opportunity at this point to install an electric radiant heat mat should that floor need extra heat. If this were a bathroom you were working on, I’d insist on it. I have a mat like this in my man cave under my laminate flooring and it produces a luxurious heat. I used the NuHeat electric floor mat and it was an easy DIY project I finished in about four hours.

This is the electric radiant floor mat that's heating my man cave ham radio shack. It's a great DIY project. CLICK the IMAGE NOW to order your own NuHeat Electric Floor Heat Mat. © 2017 Tim Carter

Last year I had the opportunity to retrofit my master bathroom floor with radiant heating and my wife’s feet are toasty warm now n frigid winter mornings. The bathroom is also much warmer with the extra heat.

Self-Leveling Pourable Compound - It's DIY Friendly

Your task at this point is to add just enough self-leveling compound so the top of the laminate flooring will be flush with the adjacent rooms. Hopefully the original builder made all the floors flush with the tile, so this should be an easy task.

Read the instructions on the self-leveling floor compound. My guess is you’ll want to use a wet-dry vacuum to get all grit and dust up from the concrete mortar. Since the self-leveling compounds require water to mix them, it might be a good idea to spritz the concrete mortar with water just before covering it with the self-leveling mixture. This ensures you’ll get a great bond and the concrete mortar won’t suck too much water from the leveling compound too fast.

If that happens, the compound may not flow like it should giving you that smooth level surface. I suggest you experiment with a bag of the self-leveling compound to make sure you have a feel for how it works. Build a small rectangle frame out of 3/4-inch trim lumber that’s 2 feet by 4 feet. Set it on a sheet of 6 mil plastic on your garage floor. Mix up some compound and pour away. The plastic will keep it from bonding to your garage floor.

Once the compound sets up, you can break it apart with a hammer with ease. You'll be stunned how easy it is to work with.

Pay CLOSE ATTENTION to the amount of water the instructions say to add. If you add too much water, you can ruin the compound.

Laminate Floor Install Videos

VIDEO 1 of 3

VIDEO 2 of 3

VIDEO 3 of 3

Column 1179