Brown Stains on Side of House TIPS Below

Brown Stains on House TIPS:

- Cedar has natural preservative chemicals that dissolve in water

- Stains originate just above metal z-flashing

- Weather conditions before stain appeared are critical

- Carpenters installed z-flashing wrong

- Cedar was not painted on back and edges

- CLICK HERE to subscribe to Tim's FREE newsletter

Pete lives near the seacoast in southeastern New Hampshire.

He emailed me the following photos on January 8, 2017, showing brown stains on the side of his house. This date provides a very important clue as to the problem. Here's what he had to say:

"My family and I built our new home (we general contracted it) and we moved into it in November of 2015. Since then there haven't been any issues with the siding, however a week ago I noticed a bunch of brown streaks/stains on the east side of the house. I thought it was bird droppings at first so I power washed it off. Fast forward a week later and the stains have reappeared in the same spot. After further research, it looks like I likely have water getting behind the cedar shingles, and from there it is going down the OSB (ZIP System) until it hits a horizontal trim piece which you can see from the pictures. From there, the water is flowing out over the trim piece and down the white James Hardie board siding.

There is a window directly above where the stains are occurring so I'm wondering if somehow water is getting in from above or directly below the window. I haven't had a chance to get a ladder out and take a closer look yet. I don't think the water is getting behind the cedar from way up above the window because you can see a horizontal trim piece above the window and there is no staining on it. If the water was getting in above that point, I expect the water would flow out once it got down to this trim piece and cause some staining up there.

It also looks like there is some very minor staining elsewhere at the corner of the house about 15 feet away from the main staining under a gutter. I'm thinking these may not be related but I'm not sure. What does everyone think is causing the staining and where is the water getting in if you had to make an educated guess?

Also, I didn't mention that the walls are insulated with closed cell spray foam and under the cedar is Benjamin Obdyke Hyrdrogap wrapping and Zip System OSB with taped seams."

Here are the photos Pete sent. Below them I'll address the possible issues and what I think is going on.

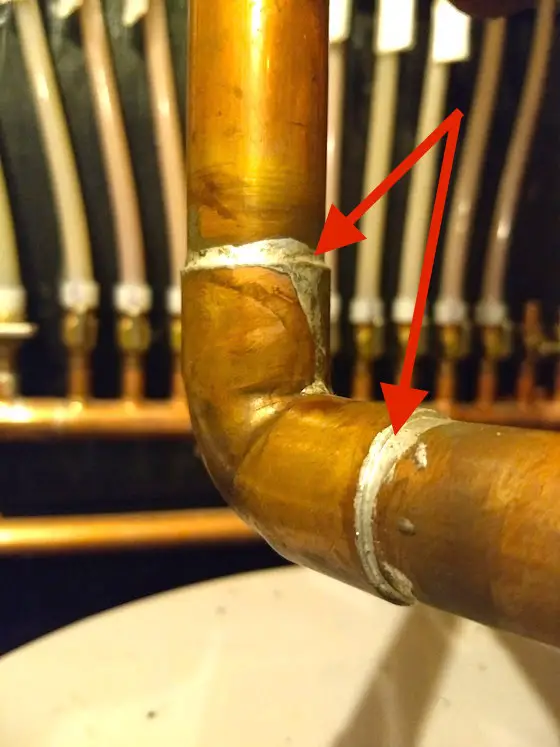

You can see the brown stains dripping down from the behind the white horizontal fascia boards. © 2017 Tim Carter via perpetual license from Pete

Here's a wider view of the situation. The red arrow points to the stains. © 2017 Tim Carter per perpetual license from Pete

Here's some staining on the underside of the gutter. There is a trace of it on the edge of the soffit. © 2017 Tim Carter per perpetual license from Pete

Here's my autopsy report dated January 9, 2017.

Here are important facts:

- The siding is cedar

- The previous year in New Hampshire was very dry and extreme drought conditions were happening where this house is located

- The stains first appeared after one year

- The stains appeared in cold weather, although there has been some rain in southeastern NH in the past month

- The z-flashing above the top white horizontal fascia board that goes behind the siding extends over to the soffit adjacent to the gutter

Cedar and redwood contain natural chemical preservatives that dissolve in water. The technical name for the stains on Pete's house are extractive chemical stains. Because they dissolve in water, that's why Pete was able to wash them off the first time.

I'm at a disadvantage because I've not been on a ladder to inspect the problem closely, but my first suspicion is improperly installed z-flashing above the topmost white horizontal fascia board.

The carpenters could have installed this flat with hard 90-degree bends instead of making the part on top of the flat edge of the white trim slope towards the outer bend. By making the bend in the metal flashing more than 90 degrees, it creates a tilted profile so water rapidly drains off.

The z-flashing also has another obvious defect. The front edge that's visible should have come down across the face of the horizontal white fascia board about 3/8 inch and then had a 30-degree bend on the last 3/8 inch of material so the bottom edge of the metal in no way touches the white board.

Allowing the metal to touch the board creates a capillary attraction issue for the water that comes to the bottom tip of the z-flashing. This water can be drawn back up underneath the metal because of the natural surface tension in water.

My guess is the carpenters didn't work with the painters on the project. the cedar siding should have been pre-painted on all sides and edges two coats before it's installed. This would prevent water from soaking into the wood and dissolving the extractive preservatives.

I'm also quite certain the carpenters probably placed the starter row of cedar shingles/shakes in contact with the z-flashing. This is a critical mistake. They should have been held up off the back bend of the metal at least 3/8 inch. If the shingles/shakes are in contact with the 90-degree metal the unpainted bottom of the shingles/shakes readily absorbs the rainwater that collects on this ledge.

The stained water on the flashing is then running over to the end corner of the house and running down to the soffit and getting onto the gutter.

Finally, my guess is the z-flashing has simple overlapping joints. I'm guessing it's also made from aluminum coil stock. You can't solder aluminum. Any lap joints should have been made with interlocking hammered flat seam joints to prevent water infiltration.