DEAR TIM: My wife wants me to install a pocket door. I have to admit that I’m pretty intimidated by this project. I don’t want to make a mistake and install a door that rubs. What’s more, I’m terrified of what’s behind the wall. Are there any tricks to installing a pocket door that will be trouble-free for years? I really need your help to get me in the right mindset. Todd B., Grove City, OH

DEAR TODD: I've been where you are now. It's easy to get intimidated about a project that you've never done or done long ago. The best way to proceed is to do as much research as possible and plan for as many problems as you might think will rear their ugly heads as you move forward.

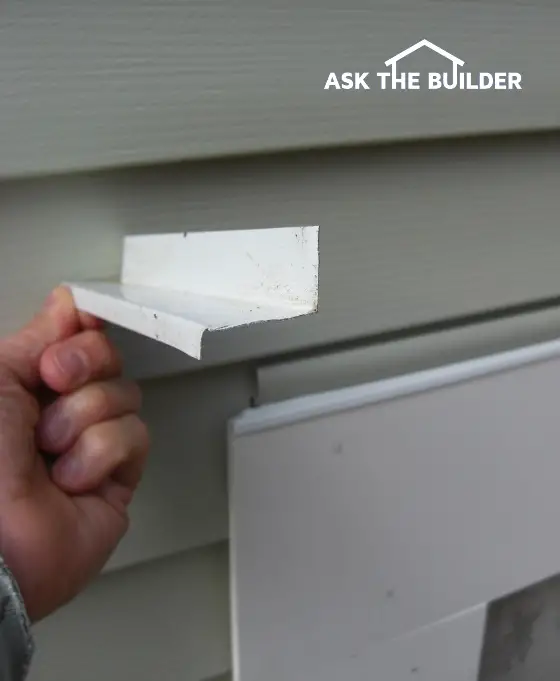

Surprise, surprise! When you go to install a pocket door in an existing home, you’re often met with challenges like these cable TV wires. PHOTO CREDIT: Tim Carter

The good news is that once it's time to install the actual pocket door hardware, you're long past the hard part. In new construction, this job is as straightforward as chewing gum. But in a remodel situation, you have to deal with walls that might be out of plumb, hidden utilities in the wall, and structural issues. All of these can be overcome, possibly with a little help from a professional if you're out of your comfort zone.

Let's talk about rubbing pocket doors. I had that problem years ago when bought what I thought was a fine pocket door frame. It was made from lumber and I just had to nail the entire contraption in place.

All went well for about nine months then I got a call from the homeowner. Sure enough the door was rubbing and scratching the paint. I traced the problem to a horizontal brace in the frame that warped inward pinching the door. I had to tear into the wall and replace that pesky piece of lumber.

Then another problem arose months later. The door kept jumping off the track. I was really upset at that door hardware.

I soon discovered you can purchase pocket-door frames that have warp-free metal studs and a track where it's impossible for the door to derail. I immediately switched to that hardware and have never had a problem in the past 25 years.

You shouldn't be terrified of what's behind the wall where your pocket door frame will nest. Virtually everything that might be a problem can be dealt with. It may not be easy to move electric cables, plumbing pipes, heating vents or pipes, or even a structural column that you uncover, but it can be done. It's all a matter of money and time.

If you're lucky enough to have your original house plans and they are detailed, you can get a handle on any structural issues. If there are nearby bathrooms under, next to or above the location where your wife wants this new fantastic door, you could have a drain stack or vent pipe in your way.

It's easy to patch plaster or drywall, so why not cut some inspection holes to see what's in the wall cavity where the frame needs to be? That should help you plan ahead before you really get started. If you move ahead, you'll be removing the entire plaster or drywall surface in this area, so it makes no difference about creating small holes at first.

To have a flawless finished pocket door, you need the best hardware and frame. I've already described that. Be sure the kit you pick has trolleys that have three wheels. These are the ones that can't jump the track.

It's really important that the frame for the door be installed in the same plane. This means that the wall can be out of plumb (not recommended), but that it can't be twisted like a pretzel. A wall that's twisted is problematic when you try to insert a non-twisted item like a large flat door.

You avoid twisted door frame rough in situations by making sure that the bottom and top plate are in straight lines and the wall studs extending between them are absolutely plumb.

Use a long straight edge to confirm this. Don't trust putting your 4-foot level on a wall stud. The stud can have a crown in it and the portion you have the level on may read level, but the top and bottom of the stud may be out of whack. All you have to do is make sure the wall studs at each end of the pocket-door rough-in opening are absolutely straight with no crown or bow in the studs.

The top of the frame that comes from the factory must also be installed absolutely level. This should not be hard to do. Use shims if you have to get it level.

Plan ahead for the thickness of the finished floor. You don't want a massive gap larger than 3/4 inch under the door. Even worse is discovering that the door needs to be cut off at the end of the project because you installed the frame too low. The high-quality pocket door frames come with pre-engineered metal wall studs that make it nearly impossible to install the frame too low.

Column 884