DEAR TIM: Several rooms in my house need closet space. The rooms are large enough such that carving out a corner will not greatly reduce the efficiency of the floor plan. What is involved in framing the closet? What is the optimal size for the closet? Do you think bi-pass or bi-fold doors work best? Is this a realistic project for a beginner? Kara F., Seymour, IN

DEAR KARA: Constructing a closet in an existing room is a perfect project for a beginner. You need minimal tools and just about 15 to 20 hours of actual time to complete the job. Here is a list of some of the necessary tools you will need: circular saw, miter box and saw, plumb bob, framing square, hammer, drill, level, drywall finishing tools, painting tools, etc.

The overall size of the closet is up to you. If it will not be a walk-in closet, I would make the finished interior depth no more than two feet. This distance will accommodate any and all clothes that will be stored on hangers. The width of the closet is up to you. Try to plan the space in such a way that any leftover existing wall space will create a cozy alcove that will be perfect for a desk, chest of drawers, or window seat.

Before you begin to construct the closet walls you should decide whether or not you want the walls to extend to the ceiling. Some of the coolest closets I have built have walls that are just seven foot tall. These partial height walls allow you create an open platform on top of the closet for trophy display, models, stuffed animals, or just plain space for seasonal clothes that can be placed in colorful plastic storage boxes.

If you decide to build your closet with partial walls, you can frame the walls on the ground and simply tilt them into place. Make the closet door as wide as possible. This prevents problems trying to reach items in the far corners of the closet once it is completed. The rough opening for most closet doors is two inches wider and higher than the actual door size.

If your closet walls will extend to the existing ceiling you should install the bottom wall plates first. Align the long wall plate so that it is 24 and one half inches away from and parallel to the existing room wall. Install your sidewall(s) plate that forms the side(s) of the closet. Use a framing square to make sure the sidewall(s) returns to the back wall forming a 90 degree

angle.

Install the top wall plates next. You locate these by using the plumb bob. Drop it from the ceiling until the bob floats just above the outside surface of the bottom plates. Move the bob to several locations along the edges of the bottom plates so that you can create dots on the ceiling that represent the top plate locations.

Cut wall studs to length for the walls. You will need a stud at all corners and at 16 inch intervals until the new walls end at the existing walls. A wall stud needs to be at the end of each wall plate. Use your level to make sure the studs are plumb. Once you are certain the walls are sturdy, the rough opening for the door is correct, and the depth and width are accurate you can install and finish the drywall and trim lumber.

I prefer to use mirrored bi-fold doors for closets. These doors open to allow easy access to the contents of the closet. Most of these come with easy installation instructions. If you choose to use mirrored doors, you must purchase them before you begin the project. The installation instructions will outline the proper rough-in dimensions. Remember, it is impossible to trim a mirrored door!

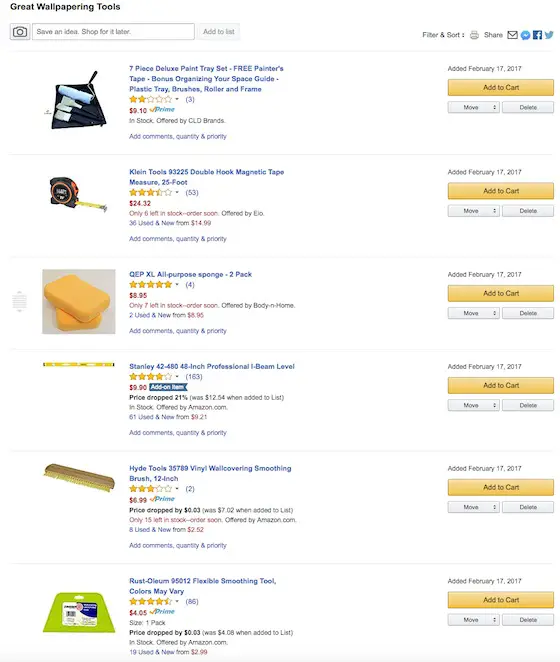

Forget about using the old plank and pole method for closet storage. Look at the many open and solid panel storage systems that are available. These can be purchased to fit just about any sized closet and will maximize the amount of storage space you have created.

Related Articles: Closet Organizers, Shoe Storage, Two Closet Plans - Materials, Two Closet Plans - Build

Get a

Get a