Tim Carter attends a factory tour where the new Lenox wood jigsaw blade is shown.

Tim Carter attends a factory tour where the new Lenox wood jigsaw blade is shown.

New subscriber? I'm glad you're here. Get ready for lots of tips.

Distinguished subscriber of digital record? Mahalo for continuing to open these newsletters.

Do you know the Paiute language? If so, you're a wise person. If you're not fluent in the ancient and beautiful language, here are two clues:

That wonderful word means straight-up land or straight canyon. You might use the words Zion National Park, the third most-visited National Park in the USA, to pinpoint my current location.

Believe me, I can attest to the number of humans who want to come here! That's why I'm leaving in a few hours, a day early, to go to the less-crowded Cedar Breaks National Monument. Let's see how my East Coast body performs at 10,500 feet above sea level!

A week before I left for vacation, I toured the Lenox Saw Blade factory just east of downtown Springfield, MA. It was an amazing experience.

Here I am in front of the giant factory. I believe it stretches over 13 acres! Copyright 2018 Tim Carter

Lenox wanted to share the news about two new jigsaw blades they've spent lots of time and money developing. One's for metal and one's for cutting wood.

The Lenox engineers did two side-by-side demonstrations with the blades against the top Bosch blades. The results were unbelievable. I recorded videos of the demonstrations.

I created a total of three videos, a column about the experience and a special page at my website that contains a once-in-a-lifetime offer for you.

Lenox is going to be giving you one or two FREE jigsaw blades.

As soon as they create the page at their website you can visit to get the FREE blade(s), then I'll share it with you. The link to the secret Lenox page will be at the TOP of the page at my website where you'll also be able to see the THREE videos, my column and lots of photos of the factory.

Why is this such big news?

I can tell you I've rarely ever had a company make such an offer to the public. You'll absolutely want to fill out the form to get one, or more, of the blades.

You can use them or give them to someone you know who can benefit from the blades. They'll make great Christmas stocking stuffers!

One Key to Rule Them All!

If you're a J.R.R. Tolkien fan, then you get that.

How would you like to have one key to unlock ALL of the door and other locks at your home? Imagine if you could re-key the locks yourself without having an expensive locksmith come to your home!

How would you like to see a DELUXE stainless-steel tool chest that has the same locks as my front door?

How do you connect an old foundation to a new one?

CLICK HERE to discover the magic of how to ensure the new foundation stays put!

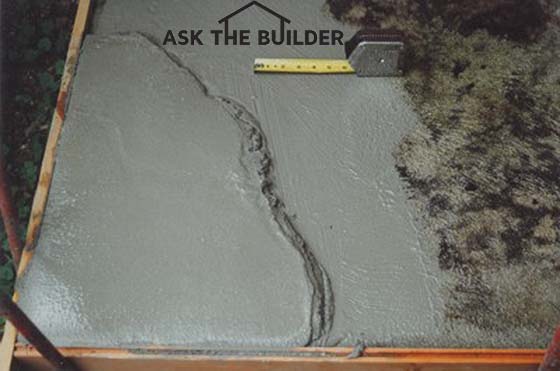

Can you see the crack in the photo below? Would you have known it was there had I not pointed it out? Doesn't it look better than any crack repair you've ever done?

CLICK HERE to see how to do it!

That's enough for a Saturday. Dawn is breaking here at Mukuntuweap.

I'll be back home late Wednesday and will have a link to MANY great photos of my trip out West for you.

Let's hope I survive the thin air today at Cedar Breaks National Monument!

Tim Carter

Founder - www.AsktheBuilder.com

Magic Powder Man - www.StainSolver.com

Radio Waves of Happiness - www.W3ATB.com

Do It Right, Not Over!

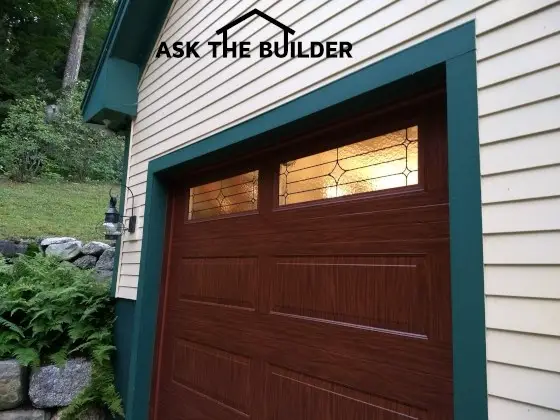

Major building product improvements have happened over the past 25 years like these bi-directional wood grain insulated steel garage doors by HAAS Door. (C) Copyright 2018 Tim Carter

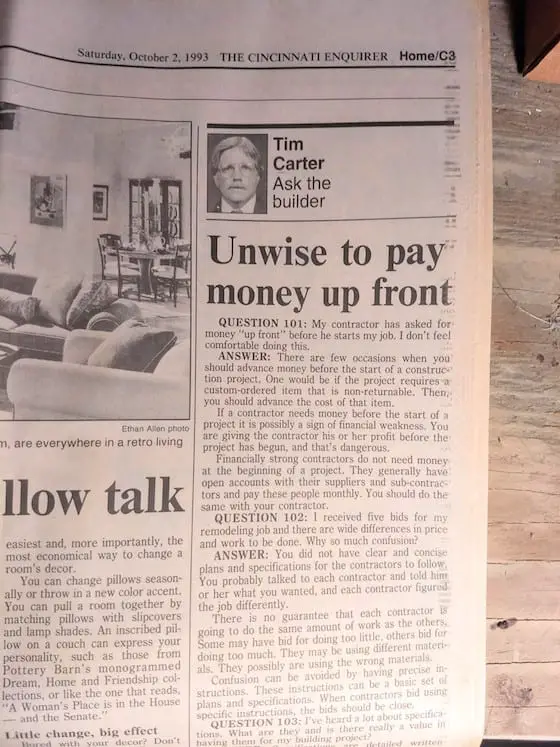

October 2, 2018 is the 25th anniversary of my Ask the Builder syndicated newspaper column. I’m very proud of surviving this long as a writer and publisher and thought I’d share some of the good and the bad I’ve seen since that morning I waited outside in the dark for the newspaper carrier to hand me my copy of the Cincinnati Enquirer.

Look at that mug shot! You'd think I'd be happy, but that's the photo the Cincinnati Enquirer wanted. I finally got my editor, Ann Haas, to accept a smiling photo of me in a flannel shirt! Copyright 2018 Tim Carter

It’s funny, but it doesn’t seem that long ago that I made the transition from a full-time custom home builder and remodeler to writer then publisher. I’m often asked by readers like you and subscribers to my newsletter how I made the successful transition.

The simple answer is I took failure off the table. I was determined to make this new career blossom because I knew that if I continued to work with my hands, back and knees, as I loved to do, I’d be crippled or fully disabled by now. As it turns out, I’m still building, but using electrons instead of concrete, wood, and steel.

This was the teaser to my column on the front page of the Tempo section that Saturday. What a ride it's been! Copyright 2018 Tim Carter

I’ve seen many good things happen over the past twenty-five years with respect to building products and I’ve seed disturbing trends emerge with respect to product longevity and the quality produced by tradespeople who build your new home, add that room addition, or install a new roof.

One thing I’ve discovered is it sometimes pays to wait before you buy a brand new product that hits the marketplace. An example is composite decking. I’ll never forget when the first composite decking product made its debut. Homeowners swooned over it. However, it took nearly twenty years for the composite deck industry to finally figure out how to make a fantastic product that will last and looks great.

I witnessed the painful growing pains of low-flush toilets. Government regulations forced manufacturers to create toilets that used far less water than ones that had worked so well for decades and decades. Most of the new toilets wouldn’t flush right. It took years for some engineers in the industry to finally figure out how to get less than two gallons of water to create a powerful flush.

Technology has also overtaken the home building and remodeling industry like an army of steamrollers. Some argue for the better, and some like my wife, despise it. I constantly test new products around my own home and Kathy hates the recessed LED light over our kitchen island that has a speaker in it. The speaker can play music from my smartphone via Bluetooth radio waves. Kathy feels the speaker is also snooping in our conversations.

She also wishes she could take a hammer to my doorbell and floodlight. I can see and hear what’s happening around my home from anywhere in the world with these devices so long as they’re connected to the Internet. Kathy hates that I can spy on her as she walks around the yard enjoying her flowers and plants.

I can spy on Kathy or anyone else in my yard. I've also got my friend Arlo to help too. Kathy hates Arlo. Copyright 2018 Tim Carter

I’m upset at the alarming and growing trend of lower quality with some building products. Hybridized framing lumber engineered to grow faster has vast amounts of less-dense spring wood growth in it. This makes the lumber more susceptible to rot, bowing, and twisting.

New lumber is nothing like the lumber of old. Look at how wide the lighter-colored spring wood bands are in the timber to the left! (C) Copyright 2018 Tim Carter

Fiber cement siding, a product that’s been around for over one-hundred years, has wood fiber in it now instead of waterproof fibers. Old fiber cement sided houses look as good as the day they were built, while my newer fiber cement siding is crumbling. Why the manufacturers don’t incorporate inexpensive fiberglass fibers like we do in concrete baffles me.

These fiber cement siding panels could be eighty, or more, years old. They're on an old house in Meredith, NH. When installed there was no need to paint them. For some reason, people decide to go down that road of no return. Copyright 2017 Tim Carter

The straw that broke the camel’s back at my house was asphalt shingles. My 30-year-warranty asphalt shingles started to go bad in just ten years and I had to replace them a few years later. I was so upset by this I wrote my Roofing Ripoff expose’ book that explains why your roof and mine are falling apart long before they should and most importantly how to avoid premature shingle failure. It’s my opinion that ethics seem to be in short supply, or missing, in the boardrooms of certain manufacturers.

Perhaps the most disturbing trend of all is workmanship quality. One could write a book on all the possible causes, but first and foremost is the removal of the incentive in high school for young people to choose a trade as a rewarding career path. That’s a grave mistake in my opinion, and you and millions of others are paying for it by dealing with more and more low-quality, uninspired workmanship that seems to be the new normal.

If I could wave a magic wand right now, I’d make two things happen. I’d bring back and expand all of the vocational school programs. Home building, as well as all trades, would be encouraged as a career in grade schools.

Young women and men would be encouraged to fill the ranks of every trade.

I’d also make ethics a mandatory course in high school, college, and a core topic at all business schools. The quest for higher and higher profits seems to put far too much pressure on the ethical aspects of business.

I want you to know that you’re responsible for the overall success of Ask the Builder. You continue to read my column and write letters to your paper editors sharing how I’ve helped you. You visit my website each day to find all of my past columns and videos that are filled with money and time-saving tips. I say we keep on going for another twenty-five years! What say you? PLEASE LEAVE A COMMENT BELOW.

Column 1266

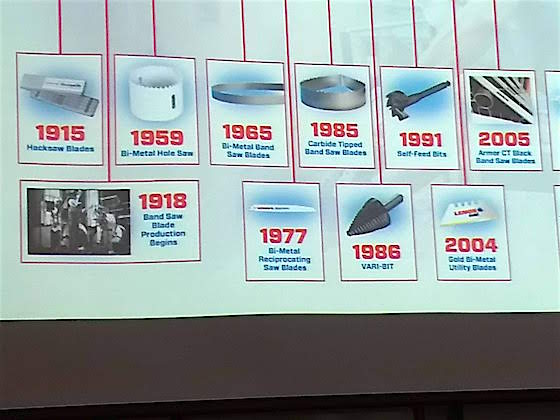

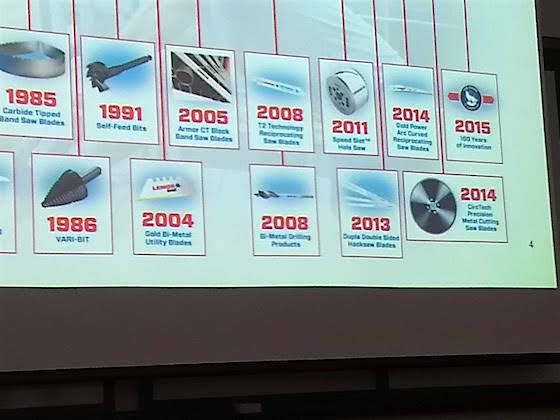

Lenox Saw Blade Factory Tour - This is just one of many types of saw blades Lenox makes at their Springfield, MA factory. Copyright 2018 Tim Carter

"Watching all the blades being made in just hours, I marveled at the demand. If all those blades are not bought each day, they start to stack up somewhere!"

I was invited to do a spectacular factory tour where they make Lenox saw blades of all types. The tour was on September 13, 2018. The full story of my visit is below. Be sure to read it. In the October 5, 2018 AsktheBuilder Newsletter and Update, Tim featured these saw blades and how you could get a free blade.

I taped three videos while there, two of them side-by-side comparisons of the new jigsaw blades Lenox was debuting at the tour. The videos are all below.

Watching all the blades being made in just hours, I marveled at the demand. If all those blades are not bought each day, they start to stack up somewhere!

Watch this video of some of what I saw. Unfortunately, much of what I saw on the tour was so secret, they don't allow photos or video to be shot. But there's some great stuff in the following video to give you an idea of what it's like in a factory.

Here are some photos you may like:

Each attendee gets a name tag with a handsome Lenox lanyard. Copyright 2018 Tim Carter

When I checked in at the hotel, a very nice backpack was waiting for me. Look at all that was inside: polo shirt, t-shirt, hat, insulated mug, expensive pen and tablet with cover, fig & cherry coffee beans, snack bars, water, and drink can sleeves. Copyright 2018 Tim Carter

This is the typical floor in much of the 13-acre factory. The wood blocks are 1 and 1/4-inch thick. They protect the saw blades from damage should they fall to the floor. The workers also appreciate it as it's easier to stand on than concrete. Copyright 2018 Tim Carter

Full Factory Tour Story

Recently I was invited to tour the Lenox saw blade factory in Springfield, MA. As I drove home from the tour I decided you’d like to know what it’s like to be inside a plant where products come off the line stamped Made in the USA.

Factory tours are often coupled with a new product announcement. Manufacturers are excited to share the news about innovation and feel that if folks like me get to see how things are made that I’ll be more inclined to share the news. Factories, for any number of reasons, are often closed to the general public. This is your chance to experience what I was lucky to see.

Lenox employees have worked for the past two years improving the ubiquitous jigsaw blade. You may own a jigsaw that allows you to cut both straight and curved lines in wood, metal and some other materials. You may also be frustrated like me by blades that dull fast or snap off at the tang up where the blade connects to the saw.

You can kick your frustration to the curb because the new blades I saw solve these problems.

Many factories are filled with the noise of production. Machines can start up without notice, things that look harmless can burn you, and you need to have your head on a swivel to ensure you don’t get hurt. You’re required to wear earplugs, safety glasses and steel-toed boots or covers to protect you from harm.

My first impression of this factory was how big it was. I’m nearly certain they said that it covered 13 acres. The plant employs approximately seven hundred humans and quite a few precision robots that help produce saw blades of unparalleled quality.

I couldn’t help but notice the floor in many parts of the factory was made up of wood blocks that were cut ends of dimensional lumber. The wood was 1 and 1/4-inches thick. It protects saw blades that might somehow touch the floor. The wood is also easier to stand on all day.

It’s important to realize that great products are derived from the hard work of all in the factory including the engineering team that works in the research and development (R&D) department. I toured the R&D section and got to see all sorts of machines that test blades and evaluate blade materials and processes. Tests are run on competitors’ blades as well as the blades Lenox is developing.

The factory floor layout reminded me of a giant real-life child’s maze. There were yellow painted lines on the floors that created corridors of safety where one walked. Some were long, others ended in a work area. Intersections often had overhead LED light fixtures that functioned much like traffic lights you encounter when driving.

Giant racks of raw materials and semi-processed materials were everywhere. Large 3 and 4-foot diameter coils of metal that looked just like reels filled with colored ribbon were everywhere. These thin strips of metal would hours later be transformed into saw blades of all types and sizes. Machines milled stacks of saw blades at once. I couldn’t believe in one eight-hour shift how many blades might be produced!

Rows of heat-treating furnaces extended down below the factory floor. The reels of thin steel bake in these giant sealed chambers for hours on end. The heating and cooling process is very complex and needs to be done with great precision so the steel has a finished quality to hold an edge yet be supple enough so it doesn’t snap under normal use.

Another key point is this factory produces giant blades for industrial users all over the world. Those were being created in parts of the plant far away from where I was. I did get to see one of these giant blades cutting its way through a 12-inch-diameter piece of solid steel in a testing chamber. It was astonishing to see a thin blade saw through a giant piece of metal.

Most of the machines and layout I saw were secret and we were not allowed to take photographs or videos in many parts of the factory. Some machines are made by workers in the factory. The machinery and the way the machines work to make things is often more valuable than a patent that covers the finished product.

One of the new processes I got to see was a micro-peening method that treats the one small edge of a jigsaw blade tang end where the blade is inserted into the jigsaw. Small pieces of ceramic are blasted at the edges of lots of blades at one time. This helps make the steel blade far less susceptible to cracking under tension. When cracks develop at the tang, the blade snaps off and you and I often spew bad language from our mouths.

At the conclusion of the tour, I discovered that Lenox had a surprise gift for you. They want to give you one of these new blades for free. All you have to do is visit the following page of my website for the direct link. You’ll also see many more photos and videos I was allowed to shoot inside the factory. Go to: http://go.askthebuilder.com/lenoxtour

New subscriber? Thanks for signing up. This issue is very unusual because of what's going on right now.

Subscriber of Record? You know every now and then, I issue WARNINGS.

First, and foremost, this is a LAST CALL notice for the Labor Day Stain Solver sale. I got busy last weekend and failed to alert you.

The sale ENDS tonight at midnight. If you want Stain Solver, act immediately.

You get 10% off and FREE SHIPPING to any of the lower 48 states.

Promo code: LBRDAY18

CLICK HERE to place your order.

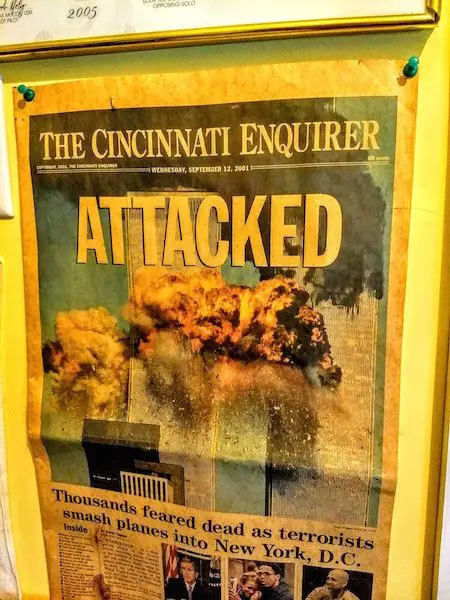

Today is the grim 17th anniversary of the coordinated terrorist attack on the USA. Just under 3,000 of my fellow US citizens were sent to Heaven in a few hours.

For years, I was drawn to the Flight 93 tragedy and wanted to visit the site of that crash. Two years ago, it happened. If you've never been to that hallowed and sacred ground in southern PA, I urge you to go.

I visited the Flight 93 site twice in ten days. The first time, I was on the plaza just 150 feet from the crash site. I was by myself just after sunrise crying my eyes out reflecting on the bravery of the passengers and their resolve to live.

The front page of the September 12, 2001, edition of the Cincinnati Enquirer hangs in my office. It shows the second plane's fireball belching from the south tower of the World Trade center and the coal-black smoke of the first plane's aftermath streaming out of the north tower into the gorgeous cloudless sky.

I have it up as a daily reminder that we're at war.

We're in a ongoing war with people who want to shred the US Constitution and impose their views and values onto you.

Never forget that we're still at war.

Don't believe me? Just read up about why the USS Constitution had to sail to the Mediterranean Sea!

Several years ago, I sent out a WARNING newsletter about Hurricane Sandy that pummeled New Jersey and New York.

Hurricane Florence is now aimed at South and North Carolina. It's going to be FAR WORSE than Hurricane Sandy.

I was able to visit Art's home a year or so after Sandy changed his life forever. He's a subscriber to this newsletter who survived Hurricane Sandy. His home had feet of water in it.

It appears the expert meteorologists all seem to agree that Florence is going to stall once she slams ashore.

This means vast amounts of rain are going to fall inland.

WARNING: You may have NEVER HAD WATER in your home before. But it can happen NOW.

If you have ANYTHING OF VALUE that's in a basement or ground floor, MOVE IT HIGHER.

If you live anywhere, even within a mile of a tiny harmless stream, your home could FLOOD. PREPARE NOW to save yourself, your pets, and ANYTHING that's valuable.

DO NOT WAIT until Thursday.

You're going to see historic river flood levels in SC, NC and possibly VA. You're going to see unbelievable videos of water RUSHING DOWN streets that have NEVER before been flooded.

Your home might be destroyed, or that of a friend or relative.

NOW IS THE TIME to make arrangements to SAVE ANYTHING of value.

How do I know this? I got hundreds of emails from Hurricane Harvey victims from last year in Houston. I got hundreds of emails from Hurricane Sandy survivors.

It's going to be HORRIBLE.

That's enough for a somber Tuesday morning. Tomorrow, I'll be driving to Springfield, MA for a Lenox saw blade factory tour.

If you live in Springfield, MA and want to do a fast breakfast meet up on Thursday morning, I can make it happen. You need to email me ASAP to make arrangements.

Tim Carter

Founder - www.AsktheBuilder.com

Clean Man - www.StainSolver.com

Happiness - www.W3ATB.com

Do It Right, Not Over!

The wood rot on this porch could have been long delayed using safe borate treatment. (C) Copyright 2018 Tim Carter

Question #1: Tim, is there some other safe DIY treatment I can do to prevent the wood from being destroyed by wood rot and insects? I’m chemically sensitive and don’t want to rely on the normal treated lumber that one buys from lumber yards. Is there a downside to DIY treatment if it exists? Ellen T., Richmond, VA

You may be like Ellen and wonder if there are alternative methods to treat lumber so it’s not so tasty to bothersome insects and wood-destroying fungi. I’ve got good news for you. A very safe process does exist and it’s rapidly being forgotten. What’s that old saying, out of sight out of mind?

It’s been known for a very long time that borate treatment of wood does an amazing job of preventing wood rot. Insects find wood that contains borates about as tasty as you find 100 percent cocoa. Yuck!

The borate powder dissolves easily in water. You simply soak the lumber in the borate solution. Most people just build a trough using 6-mil plastic sheeting. The different borate chemicals come with instructions telling you how to mix the powder with water and how long to soak the lumber.

If the lumber has painted ends as used to be the standard, you may want to cut off a thin wafer to expose fresh unpainted end grain. It’s important to realize that the cellular structure of trees and lumber is much like very long drinking straws that are bunched next to one another running up the entire tree. The borate chemicals are drawn far up into the lumber through the end grain.

Two soaking treatments are better than one in almost all cases. The wood needs to be stacked in the shade with thin strips of wood between the layers so it can dry. Once dry, you can paint the lumber or stain it on all sides and edges before it’s installed.

The borate treatment has a significant drawback. The borates can be leached from the lumber if you leave it outdoors. It’s an excellent treatment for lumber that’s going to be used to build a home covered with a roof and any lumber that won’t get wet as would a deck or other outdoor structure.

I’d highly recommend this process for all lumber that’s used to frame a floor above a crawlspace. It’s also a great idea to do this for large pieces of solid wood that are going to be used to create beams that might be used in crawlspaces.

I’ve assembled lots more information about borate chemicals, where to buy them, and borate-treatment videos for you at my website. Go to: borate

Question #2: Tim, can you settle a disagreement? I told my wife it’s a good idea to build a shed on a slab larger than the shed. This provides a concrete walkway around the shed and I can lean tools up against the shed keeping them out of the dirt. My spouse thinks my plan is foolhardy. She maintains that driving rain may leak under the wall into the shed. She also thinks the wood walls and siding of the shed will rot faster. I’m sure you’ll see the brilliance of my idea. Stuart T., Riverside, CA

I’ve been happily married for just over forty-four years. There’s more than one reason for that and one of them happens to be the art of listening. Don’t be like Stuart and dig in so deep you can’t see the wisdom of another solution.

It turns out building a shed or any other building on a slab that’s larger than the outer walls of the structure is a very bad idea. Oh, I’m sure you can make all sorts of arguments about amazing caulks that would stop leaks, slanting the exposed concrete so it drains, and other flimsy debate points.

The art of keeping water out of buildings is ancient. My guess is builders thousands of years ago looked at how animals stayed dry. There’s a reason the feathers of birds overlap in a certain way.

Your roof shingles overlap one another to shed water. Clapboard siding overlaps one on top of another to do the same. The first piece of siding material on your shed should overlap the outer edge of the concrete slab so no water leaks under the wall.

I’ve got a great illustration of how this overlap should happen, as well as great exterior wall-building videos on sheds at my website waiting for you. Go to: overlap

Column 1265

New subscriber? It's pretty casual around here. I hope you don't have any holes in your socks.

Subscriber of Record? Don't forget to use coasters for goodness sakes!

You know winter's coming when you wake up and for the first time you see vapor rising up off the lake. It was 50 F this morning here in central New Hampshire when the sun came up over the horizon, yet the water temperature of the lake is probably 75 F.

This is a SPECIAL ALERT issue of the newsletter.

I watched a short video promoting a DIY magazine a few days ago and was aghast at what I saw in the video.

If you're a seasoned subscriber you know it's very RARE for me to bash a competitor. There's usually not much to gain.

But what I saw in the video was so bad, I couldn't give them a pass. If you're a subscriber to this magazine let it be a warning to you that some of what they publish may not be good advice!

Tell me if you can spot the flaw in this screenshot I captured from the video:

Are you unable to see the major flaw? I'm talking a SERIOUS FLAW.

CLICK HERE if you can't figure it out and more importantly want to see how I would have done this job.

One of the things I enjoy doing best at AsktheBuilder.com is curating and preserving methods and products that transition from history to legend to myth.

There are countless examples of this happening all the time. There are great methods of building that are being kicked to the curb all the time. I'm trying to prevent this information from being lost as was the ring in Lord of the Rings.

For example, do you know about cement paint?

I didn't think so. Here's a photo of cement paint. Do you know why it's used? I didn't think so. CLICK THE PHOTO to discover WHY you need to use it.

What about DIY wood treatment? Do you know a very cool way to prevent wood rot? It's a method that's rapidly becoming myth. Look at this photo and understand the wood rot could have been prevented.

It's all about treating wood with a safe borate solution BEFORE you install it.

CLICK HERE to discover how to do it and WHERE to BUY the safe and effective borate powder.

How would you like to have a gorgeous Queen Anne Victorian shed in your yard? Click the link just below the photo of a shed I built for my wife Kathy at our Cincinnati, OH home.

CLICK HERE for LOTS of shed-building tips.

A vast majority of sheds are too small. I've got a VIDEO in the above column that shows you how to ensure your shed is never too small. It's such a SIMPLE THING to do to ensure your next shed is perfect. CLICK HERE and scroll down to see the video.

That's enough for a Sunday morning.

Are you on the East Coast? Are you ready to be without electricity for a week or more? Hurricane Florence is about to make herself felt.

Don't count on the fire department coming to help you.

Your home is the LAST THING that's on their Community Asset List. Sorry for the tough love. It's true.

Tim Carter

Founder - www.AsktheBuilder.com

Certified Organic Man - www.StainSolver.com

Happiness Waves Man - www.W3ATB.com

Do It Right, Not Over!

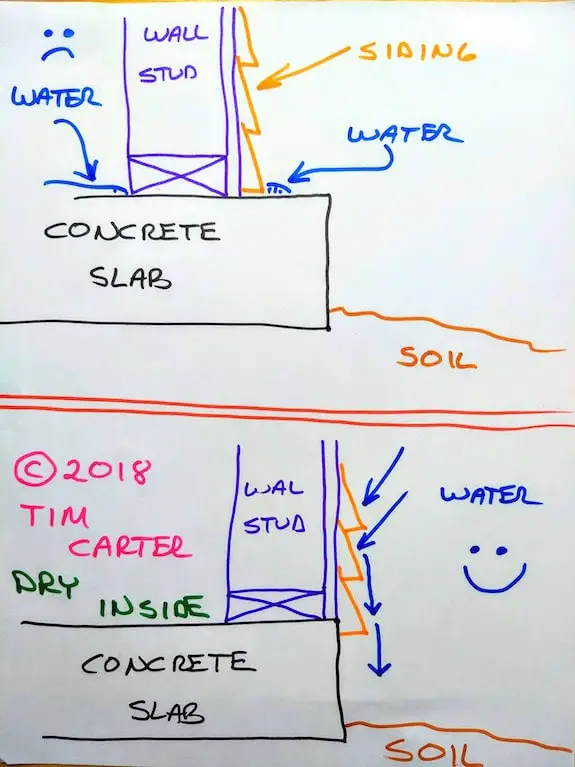

Note the exterior wall on slab. The slab is far bigger than the shed. This is the worst possible way to build. Water in a driving rain will leak into the shed under the wall and wood rot over time is guaranteed. Copyright 2018 Family Handyman - Photo used per the Fair Use Doctrine.

"I do NOT make a normal practice of bashing my peers, but this instance is so egregious I had to point it out."

This column was SO GOOD that I shared with the 31,000 subscribers who read my September 9, 2018 AsktheBuilder Newsletter.

An exterior wall must be placed on the outside edge of the slab so the exterior siding laps down and over the edge of the slab. This prevents water from leaking under the bottom of the wall to the inside of the building.

Related Links

Consider a Wood Shed Floor - Treated Lumber Joists AND Plywood!

Queen Anne Victorian Shed By Tim Carter

I was prompted to create this page because of a short video and magazine cover created by Family Handyman. They were building a retro shed on a concrete slab.

The issue I had is the entire shed sat inboard on the slab. There was at least a 16-inch border of concrete slab showing as you can see in the copyrighted screenshot I captured using the Fair Use Doctrine.

Building this way promotes wood rot and it invites water into the shed. It's the worst possible way to set an exterior wall on a slab.

It's important to realize that the information you see in other publications is not always accurate and in your best interests. My guess is the editor of Family Handyman magazine who approved this project has never had to replace a rotted wood wall or rotted wood siding on a shed built this way. She or he also has never had to deal with water leaking into a shed is another guess.

I do NOT make a normal practice of bashing my peers, but this instance is so egregious I had to point it out.

Free & Fast Bids

CLICK HERE to get FREE & FAST BIDS from local shed builders.

The following illustration shows you a cross-section of what Family Handyman is promoting in the top view.

The bottom side view shows the proper exterior wall on slab placement. Ideally, you'd want at least 6 inches of slab exposed between the bottom of the siding and the start of the soil.

The top side view is the WRONG way to build. This is what you see happening in the Family Handyman magazine cover. The cross-section at the bottom is the best way to build. There's no way water is going to get into the shed if the siding laps over the edge of the concrete slab. Copyright 2018 Tim Carter

Here are two videos that do a good job of showing you a better way to build.

In the first one, the homeowner or contractor goes the extra mile and has his wall OVERHANG the edge of the slab by 1/2 inch! You'll see this about one minute into the video.

CLICK HERE to get FREE & FAST BIDS from local shed builders.

New subscriber? Welcome! The beverages and appetizers are in the other room. My good friend Dan will be around soon with a platter of delicious cannoli. There's no need to tip him.

Old salt subscriber? Be sure to remind the newbies that we all have to clean up after ourselves.

Did you know that the word cannoli is already plural? I didn't know that!

If you eat peanut butter and jelly sandwiches or have caramel corn while you work, you might end up with sticky hand tool handles.

Or, you could cook them like happened to subscriber Trish. She sent me this email a few days ago:

"Again I turn to you when I cannot find the answer to my question.

Hubby bought tools (screw drivers, pliers etc.) with ergonomically correct handles. We moved into a home that has a shed attached in the rear. All the tools were stored there in the famous Red Tool chest.

Due to, what we believe to be, excessive heat all the handles on the tools are now wet and sticky and nothing we have tried will change the effect.

Do you have any idea what we can do or must we just replace all the tools? The handles are mushy and appear ruined. I thought maybe varnish might help but wanted to ask you first.

Thanks for always being there for us."

Have you had a similar experience with hand tools? I want to see how widespread this problem is.

If so, would you take this short survey to help others?

CLICK HERE for the Sticky Hand Tool Handle survey.

On Labor Day, an elderly couple was hurt in a deck collapse. They're both alive, but it could have had a more grim outcome.

CLICK HERE to read the short story. The Des Moines Register website will have you pulling your hair out trying to see the story. You may have to slide the headline up to see the story.

The only reason I bring this up is that deck collapses are more common than you think. Decks, like any other thing, have a life expectancy.

Some are short because inferior methods are used to construct the decks. The following is a photo I shot of a new deck being built on my street. I'd NEVER go out on this deck if invited to their home.

You may wonder what's wrong? Maybe your deck post, deck beam, and deck joist connections look like this.

The beam is made up of three joists, the wood you see with the white labels stapled to them. See the small toenails coming up into the beam from the post below. WRONG!

See the two small toenails in the joists above the beam that go down into the beam? WRONG!

The carpenter should have used metal structural post-to-beam connectors with approved screws.

Carpenters might not be using the correct fasteners with the approved galvanized coating to resist corrosion caused by the HIGH copper content of newer treated lumber.

If you feel your deck might be at risk, have it inspected by an ASHI home inspector.

SAFETY TIP: If you're at a party at someone's home and there's a gathering on a deck where people are dancing, GET OFF THE DECK. Dancing can cause decks to sway back and forth or pull away from the house.

Ian came to my website overnight looking for advice on how to install fence posts. He left a comment asking:

"I have pure sand for soil around here. Can I just fill it back in with the sand around the post? 6ft dog ear wood fence with 4x4x8 posts and a 2.5ft hole."

I've got lots of experience with this as I've built lots of fences and I've interviewed others who have installed thousands of them.

The best way to install fence posts is in this column:

CLICK HERE if you want to see the column.

Ian poses a very good question because many don't have sand for soil. Many soils have a clay component.

But had Ian focused on why crushed gravel makes the best material, he'd have come away that sand might work for him. After all, sand is just tiny pieces of rock. The issue is most sand tends to have rounded edges, not an angular shape.

Sand will work, but crushed rock is better.

I've got two new products for you to look at. Great photos here. CLICK HERE to see a new lightweight extension ladder I just got. I LOVE IT!

You'll also see a small power pack that can power all sorts of your things AND jump start your car or light truck! CRAZY it can have that much stored energy!!!

Remember, Stain Solver is on sale for just a few more days!!! ORDER NOW

Promo Code:

LBRDAY18

CLICK HERE to order.

That's enough for a Thursday.

Tim Carter

Founder - www.AsktheBuilder.com

Cleaning Crystals - www.StainSolver.com

Invisible Happiness - www.W3ATB.com

Please take the following survey if you have hand tools with sticky handles.

Subscribe to the FREE Ask the Builder newsletter to receive professional advice for your home. Complete the form below and each week you'll get:

Unsubscribe at any time. We respect your email privacy.