Crown Molding - Traditional Cutting Methods

Cutting crown molding has driven many a person nuts! Years ago, I was one of them. In fact, I just received a wonderful note from Milton Grant in Clinton Township, Michigan. Milton wrote, "...I have tried your system of cutting the moldings in a miter box while it is sitting as it hangs on a wall. I have also used a Delta Sidekick compound saw. Results - My greatest product is sawdust, for which I have no market."

Well Milton, your days of producing vast quantities of useless sawdust are over! Once you have finished reading this article, it is my hope that you will completely understand the process!

Test Pieces

I think one quick way to success is to cut some small test pieces of crown molding so that you can see how the joints actually work. With these test pieces in hand, you can use them to check the corners you are about to work in. The test pieces tell you whether or not the corner is square. If a corner is out of square - and most are - you can see how much you need to adjust your saw cut to make the joints perfect or nearly so.

Get Some Junk Trim

Go to a lumber yard and buy the least expensive crown molding you can find. You are going to use this to experiment with.

I would get possibly two 8 or 10 foot long pieces. I would cut 16 inch long pieces until you get very good at the process. This tutorial material will really come in handy as you teach yourself how to adjust the saw angle to compensate for corners that are not 90 degrees.

Odd Angles

Okay, so you mastered cutting inside and outside corners that are 90 degrees or nearly so. Now you ask, "Tim, I have a 45 degree and a 30 degree bay window area in a room. How do I make the angles work there?" No problem! If you know the intersection angle of the walls, then you simply divide that by 2 to get the saw cut angle.

Let me prove it to you. Your 45 degree angled bay is actually just part of an octagon, or eight sided object. To install crown molding at any of these 45 degree corners you just set the miter box saw at 22.5 degrees. The cut on the molding will look similar to your other cuts, it will just not be as long. Go ahead, cut two test pieces as I have shown on the other pages of this bulletin. They will look a little odd, but I bet you they will meet very closely or perfectly up in that bay corner.

Would you like step-by-step photos and instructions that show you how I install crown molding anywhere in a home? If so, you might want my Instant Download Crown Molding eBook.

But, if you want to actually see me install crown molding in all the same places while watching an action-packed interactive DVD that was filmed in High Definition, then you may want my Crown Molding DVD.

Positioning is Critical

When you hold the crown molding upside down in the miter box saw, you must position it very carefully. If you do not hold each piece you cut the same way in the saw, the angled face will get longer and shorter and this will make for an imperfect joint. Use your scrap inexpensive crown molding trim and test this. Twist a piece ever so slightly and see what happens. You may have only rotated the trim one sixteenth of an inch in the saw but the angled cut grows by an eighth of an inch or more!

Click here to watch a video on cutting crown molding the easy way.

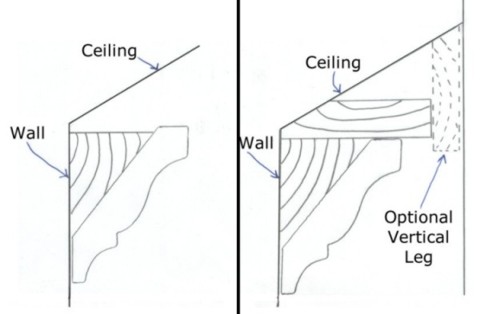

The Hidden Triangle

Cutting crown is bad enough, but nailing it can be even worse. If your nerves are on edge from cutting frustration you will TILT when you go to nail it if you have not installed the simple triangular piece of rough lumber in the void space behind the trim. If you are using the standard 3 and 1/4 or 3 and 5/8 crown, a 2 x 2 cut diagonally on a table saw yields two perfect pieces. I like to leave a 1/8 inch gap between the back of the molding and the block for adjustment purposes.

Remember, my Crown Molding eBook has complete step-by-step instructions with tons of color photographs that show you exactly how to cut crown molding. 100% Satisfaction Guarantee!

Column B354