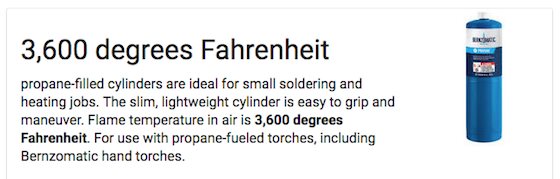

See that cool blue flame? It's anything but cool. Put a sensor in the white area and it will probably measure 3,600 F. Copyright 2018 Tim Carter

PR Blunders - Be Very Careful and Use Common Sense

Published: January 17, 2018

I'm a member of the working press covering the home improvement beat. My syndicated newspaper column Ask the Builder still runs in sixty newspapers across the USA.

At the present time, public relations (PR) firms send me press releases each week sharing news about new building products. I received one this morning that had me shaking my head.

The press release is just below and I've included the grammar, misspelling and style errors.

I've DELETED the manufacturer and product name as well as the PR company/contact to avoid a legal dustup in case they feel I'm libeling them. Their names are really not that important. What you should focus on is the message in the press release.

After you read it, I'm going to slice and dice it for you.

Hi Tim,

As much as we’d like it to, home maintenance doesn’t stop when the temps drop. Cold weather means slippery sidewalks, frozen padlocks and high heating costs. I wanted to share some DIY tips and home hacks for the winter season that can be done with just one tool – a blowtorch.

Here are 6 (stylebook suggests spelling out 'six') easy to handle winter home hacks:

Don’t get locked out: Use a _____ torch to prevent lockouts by thawing a frozen padlock with a few quick strokes of heat.

Avoid slips and falls: Use that same ______ (or, the _______) to melt snow and slippery ice patches covering your walkway or steps. Then use a broom to brush away the rest. BONUS: This technique works faster than using salt.

Loosen your garden hose from the faucet: Use your ________ to loosen and remove a garden hose that is frozen to the spigot. Move the torch around the spigot to spread the heat around (don’t leave on one spot). This will keep cold air from freezing your pipes.

Replace old weather stripping: Make sure your windows are sealed to keep heating costs down. Use a micro-torch to heat and remove old caulk and a paint scrapper (should only have one 'p') to peel away, then replace with new sealant.

Stay warm with an indoor fire: Wood damp from snow? No problem - use a _____ torch to light logs for an indoor fire.

Light burners on a gas grill: In the event that burners are not working, use a ______ to light the grill. Just be sure to put the torch in the grill before you turn on the gas.

The torches are available at Home Depot as well as other national hardware retailers. Photos and more information is (should be 'are') available if you’re interested – please let me know what you think!

Thanks, PR Woman's Name / Firm Withheld

Master Plumbers and Blowtorches

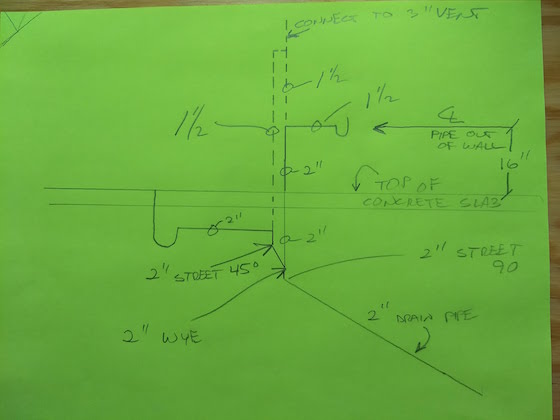

I've been a master plumber since age 29. A blowtorch in conjunction with my lack of experience created a scar on my hand that's been there for about 30 years.

A third-degree burn scar is in the center of the red oval. Blowtorches can do serious harm in seconds. The voice of experience talking. Copyright 2018 Tim Carter

A drop of molten lead from a blowtorch dropped onto my hand while it was crammed into some tight framing. I was unable to move my hand to get rid of the sizzling metal and a third-degree burn was the end result.

A blowtorch fueled with propane develops a flame temperature of 3,600 F degrees.

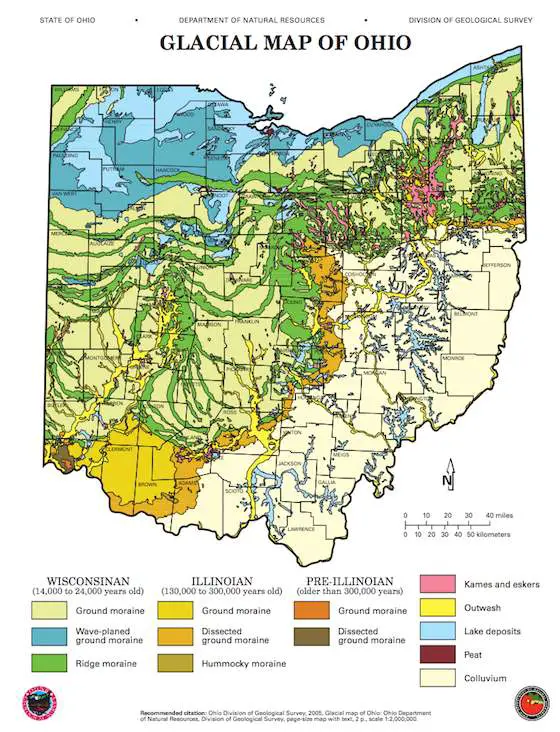

Propane can burn hot. You can melt several metals with this kind of heat. Combustibles ignite in seconds. Copyright 2018 Google, Inc.

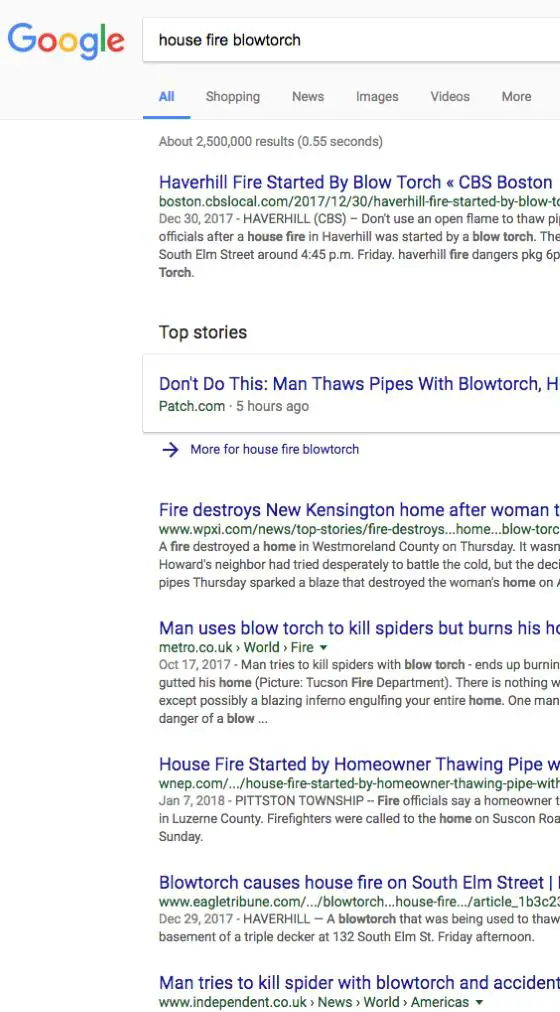

If you decide to use a blowtorch fueled with propane anywhere around your home, you can start a fire in seconds. I know as I've started more than one house on fire while soldering copper fittings. Fortunately I had planned ahead and had buckets of water nearby in case something when wrong.

The Internet is littered with thousands of blowtorch stories that ended badly. Some where people have died. It's insanity someone would recommend the use of open intense heat near combustible materials. Copyright 2018 Google Inc.

What's Wrong With This PR Blunder?

The first thing to remember is this press release is going to be printed word for word by many news outlets and a plethora of inexperienced hobby bloggers. You'll be able to do a Google search using quotation marks surrounding select sentences above to find news outlets where the above press release will be published in all its glory.

Young people who have never used a blowtorch are going to follow the tips.

Allow that to sink in. Young people will be working with open flames producing intense concentrated heat.

Another key point is the manufacturer of the blowtorch approved the press release. They are culpable for being the source of the questionable tips.

The manufacturer instructs the PR firm to put out messaging to sell product in different seasons. That's how it works. Ask any PR person.

Let's look at each of the six tips above:

Tip 1: Let's say that padlock is against a $6,000 fiberglass door. Within seconds you'll scorch the fiberglass. A painted wood or steel door will suffer immediate damage to the paint.

Tip 2: That 3,600 torch temperature is going to cause concrete to spall in just seconds. The rapid expansion of the ice-cold concrete will create pop outs in no time.

Tip 3: Have you ever been inside an old house to see what's behind a hose bib or faucet? You'll likely discover old newspapers, dust, wood chips from drilling the hole, etc. Hot gases from the torch can ignite those and a fire start all while you're outside using the blowtorch.

Tip 4: Want cold glass to crack? Remember, the tip is to do this now, not mid-summer. Just get a micro-torch tip near cold glass and watch what happens.

Tip 5: I'll grant them this tip. A blowtorch might help you get a wood fire going, but dry kindling is far better.

Tip 6: There's not a firefighter I know that would think using a propane torch is a good idea to light a grill that's malfunctioning. There's a reason the grill is not working right. Install new spark igniters.

PR Firms Have a Fiduciary Responsibility

I emailed the woman who sent me this press release warning her of the dangers.

She responded saying, "Thank you for your feedback. Each technique listed was vetted and approved by ________ engineering team for their safety."

I responded telling her that all she has to do is pass the press release by any firefighter and then added, "Your PR firm has a fiduciary duty to ensure the public is protected and for you to just *trust* the information given to you by the client is okay is naive at best."

An hour later she emailed saying, "Thank you for flagging your concerns. We are discussing with ______."

It's my opinion that PR firms have a responsibility to protect the public. These companies are paid professionals and if they belong to any associations they're bound by a code of ethics. The code of ethics for the Public Relations Society of America states:

- Act promptly to correct erroneous communications for which the practitioner is responsible.

They shouldn't be going around spreading information that could harm or kill someone. They should push back against their clients and use common sense.

I'm waiting to see how long it takes for the PR firm to correct the erroneous information they circulated.

That's how I feel. What's your take? Leave a comment below.