The mildew and algae on this vinyl siding can be removed quickly with a solution of oxygen bleach. (C) Copyright 2017 Tim Carter

How To Clean Exterior Siding TIPS

- Trees create micro aerosol sugar food

- Mildew and algae eat the sugar

- Clean with Stain Solver oxygen bleach

- Pressure washing can cause MOLD

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

DEAR TIM: My primary home and a camp I own in the woods both are covered with siding. One is wood, the other is vinyl siding, and both are dirty.

In the past few years, I've been stunned to discover mildew and algae growing on the vinyl siding. I thought vinyl siding was supposed to be maintenance-free, that's why I purchased it.

What's going on? Should I just drag out my pressure washer and get to work, or is there an alternative method to clean siding on houses? Patrick O., Fryeburg, ME

DEAR PATRICK: Each week I receive emails from homeowners just like you. They share your astonishment about having to clean their vinyl siding. Many homeowners are not too happy as the salesmen's claims about no-maintenance seem to be as hollow as an old log.

IMPORTANT TIP: Maintenance-free is a myth. All exterior surfaces must be cleaned on a regular basis. They include:

- siding

- decks

- windows

- docks

- roofs

CLICK HERE to get FREE & FAST BIDS from local handymen who can easily clean your siding.

I've seen hundreds of printed ads, heard countless radio commercials, etc. with these maintenance-free statements when it comes to exterior home improvement products.

Decking, siding, railings, fencing, etc. are often touted as requiring no future care. As you now know, it's just not true. Certain products are absolutely reduced-maintenance, but not maintenance-free.

Algae & Mildew Food

You're probably wondering how mildew and algae can survive on plastic, or vinyl siding. The mildew and algae are feeding on sugars, dust, dirt, or other things that are attached to the siding.

Many people are unaware that trees, both evergreen and deciduous, often broadcast ultra-fine aerosols of sugars at different times of years. Park your car under certain trees, and you'll discover thousands of tiny droplets of sap or sugar on the painted finish and glass.

This is yummy food for mildew and algae!

Wood Stain Food

When it comes to wood siding, the mildew and algae are possibly feasting on the actual stains and sealers you may have used to preserve the wood. Many clear and semi-transparent wood sealers and stains are made with alkyd or oil resins.

These natural oils are also delicious food for mildew and algae. Some of the sealers and stains contain chemicals that are designed to prevent mildew and algae growth, but these chemicals do breakdown when exposed to sunlight and repeated exposure to rainwater.

Spiderman® Power

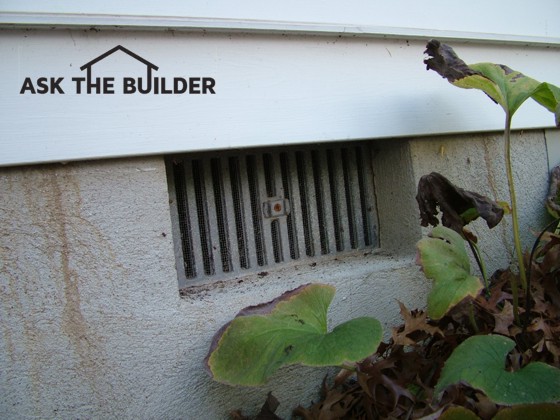

I know that you may love your pressure washer because it's a cool tool, but it can wreak havoc with houses if used improperly. Pressure washers are like Spiderman® - "With great power comes great responsibility."

The water that's ejected from the tip of the pressure washer wand can be driven into cracks and crevices where water is not supposed to go. The intense water stream can and will erode the lighter-colored spring wood in your wood siding causing it to look older than it actually is.

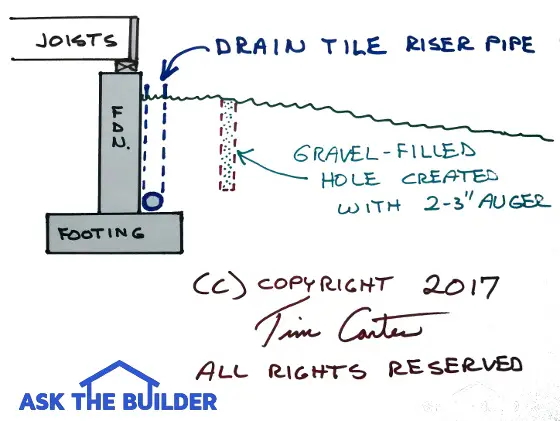

Water Behind Siding

Water driven behind vinyl siding at lap joints and corners can cause wood rot if your house lacks a proper weather barrier under the vinyl siding. Believe it or not, this requirement was lacking from the building code for many years.

There are tens of thousands of houses, maybe hundreds of thousands, that do not have a weather barrier under the siding. The siding is nailed directly to wood sheathing.

CLICK HERE to get FREE & FAST BIDS from local handymen who can easily clean your siding.

Stain Solver

Stain Solver is MADE in the USA with USA ingredients that are food-grade quality. CLICK THE IMAGE to order some NOW.

Perhaps the better way to clean the mildew and algae off your house is to use a hand-pump garden sprayer, some Stain Solver certified organic oxygen bleach and a brush on a pole. I just demonstrated this method last week to a homeowner, and he was amazed at how well it worked.

Don't confuse oxygen bleach with chlorine bleach. Chlorine bleach can remove the color from wood siding, and it can kill expensive landscaping around your home.

Stain Solver oxygen bleach will not remove color from wood, and it's safe to use around plants and animals.

Easy DIY Use

To clean your wood and vinyl siding, you just mix the powdered Stain Solver with warm water, stir till dissolved and then apply it generously to the siding.

It's best to work when the siding is in the shade. Allow the solution to fizz and bubble on the siding for about ten or fifteen minutes. Scrub with the brush and rinse with clear water from a garden hose. The siding should look brand new once dry.

RV Brush Best

Use the type of brush on a pole RV owners use to clean their expensive vehicles. An RV brush will not scratch automotive paint, so you know it's perfect for your vinyl siding.

This is a perfect brush to clean vinyl siding. It's got an adjustable handle and the perfect bristles that remove dirt loosened by using Stain Solver oxygen bleach. CLICK THE IMAGE NOW TO HAVE THIS BRUSH DELIVERED TO YOUR HOME.

Apply Dry

It's always best to apply the oxygen bleach solution to dry siding. This allows the solution to soak into the wood and deep clean it. Oxygen bleach can and will remove sun-damaged wood sealers and stains from the wood. It can absolutely remove sun-damaged and oxidized paint pigments from painted surfaces.

This makes it an excellent product to use if you're getting ready to re-stain or repaint your home. You want to remove these damaged finishes before you apply new.

Clean Twice a Year

For periodic cleaning to prevent mildew and algae buildup, just wash your home twice each year with a solution of liquid dish soap, a small amount of Stain Solver and water. Remove the sugars from the siding before the mildew and algae sit down at the table to feast!

CLICK HERE to get FREE & FAST BIDS from local handymen who can easily clean your siding.

Column 987