Concrete Deck Foundation Details | This round concrete deck foundation pier may look shabby but it’s quite possible it’s installed correctly so the deck post will not fail. (C) Copyright 2019 Tim Carter

Deck Foundation

DEAR TIM: I’m concerned about the concrete deck base that’s fully above ground at my new home. The other decks in our development have the concrete piers below ground. Shouldn’t the concrete be completely buried to protect against freezing and cracking in the winter months? What do you feel are the best concrete deck foundation details? Jeff K., Falling Waters, WV

I don’t know about you, but I love questions like Jeff’s. I can absolutely understand his concern based on the data that he’s considering. When you think about it, it’s not far-fetched to think that his deck foundation piers are wrong when his are the only ones that look like it in the neighborhood! But you and Jeff need to cast a wider net to gather more data points that will give you the comfort that your job was done right. Trust me, the truth is out there.

But think about this: Is it possible the carpenter that built Jeff’s deck was the only good one in the development and the other ones are ill-informed and lack critical thinking skills? You bet it’s possible. I see it every day in the photos and emails I get on my website.

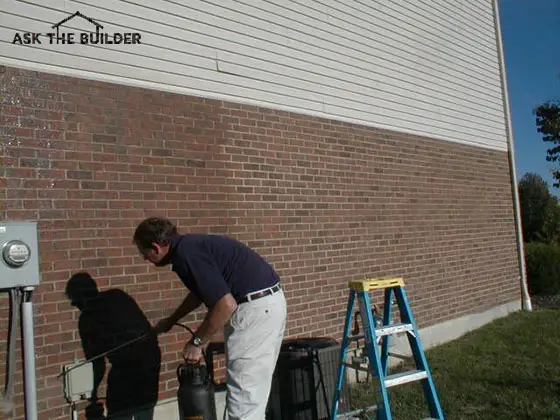

The two photos Jeff sent me show me that the builder or carpenter got everything right as far as what’s supposed to happen above ground. It would take less than an hour with a round point shovel to determine if the deck pier extends below the frost level and has a wider concrete footing that the circular deck pier rests on.

(C) Copyright 2019 Tim Carter

Let’s discuss Jeff’s deterioration concerns first. Concrete is an artificial man-made rock. If it’s mixed and installed properly for the local weather conditions, it can last for hundreds of years. All you have to do to prove this is visit a few railroad bridges in your area that have poured concrete abutments that support the bridge structure. I’ve seen concrete bridgework that was put in in the early 1900s that looks in excellent shape.

You can also look around to see above-ground poured concrete house foundations in your area that might be eighty, or more, years old. It’s all about adding enough Portland cement to the mix and making sure you don’t add too much water to the mix or use water to finish the concrete. Curing the concrete to slow the release of the mix water is also very important.

Jeff is probably worried about frost heave and/or he should be. Soils that contain water in freezing climates can expand and they go up in almost all cases. Here where I live in central New Hampshire, the soil around my house goes up at least 3 inches each winter. It can go up even more if there’s an active spring under the soil. Ice lenses grow and grow pushing the soil above them higher as the bitter weather drives the frost deeper in the soil.

Builders, engineers, architects, and building inspectors are all aware of the frost depth in a local area. I’ve got a drawing on my AsktheBuilder.com website showing the frost depth across many areas of the USA. If you live in the farthest northern reaches of Minnesota or Maine, you might have to dig down at least 6, or more, feet to get a foundation footing below the depth that frost penetrates!

You want your deck piers to be below the frost level so the deck doesn’t lift up. This kind of unwanted force can cause severe structural damage to the deck.

I’ve worked with many architects and engineers in my building career. Most of their plans all agree. It’s important to realize you need to spread out the concentrated load of the deck posts across as much soil as you can. Usually, a 6 or 8-inch-thick 2-foot-diameter poured concrete pad below the frost depth is sufficient to distribute the weight of the deck.

There are all sorts of ways to install a deck foundation base or pier. I can think of no less than ten off the top of my head. The most ingenious method I’ve seen to date, and I used this on my own deck and for shed foundation piers I built four years ago, is a plastic deck pier form you snap together on the job site. It even comes with all the required pre-bent and pre-cut reinforcing steel rods! I’ve got several videos of this marvelous deck pier system on my website.

This deck pier form is designed so its base is flared out at the bottom so it spreads out the concentrated load. You just dig the hole to the correct depth, make sure the soil is compacted, set the form in place and then immediately backfill around the form with the soil you just dug out of the hole. Add this soil slowly so you make sure the form doesn’t move.

You then fill the form with the concrete, place the anchor bolt for the post base and wait one day to start building the deck.

I prefer to have the top of my concrete deck piers at least 4 inches above the final grade around the piers. I don’t want my treated lumber posts buried in the soil as I’ve seen them rot and be a food source for termites. I always use a galvanized steel post base that keeps the bottom of the wood post up and off the poured concrete. This allows water to drain away from the wood.

Column 1323

Amanda will probably have to apply several coats of a silane-siloxane water repellent on her stone facing. This might solve the problem. If not, she may have to apply a thicker clear sealant that’s brushed on the mortar and overlapped onto the artificial pieces of stone.

Amanda will probably have to apply several coats of a silane-siloxane water repellent on her stone facing. This might solve the problem. If not, she may have to apply a thicker clear sealant that’s brushed on the mortar and overlapped onto the artificial pieces of stone.