Laconia's Public Library. Copyright 2017 Tim Carter

Old vs New Construction TIPS

- Complex question - not easy to answer in limited space

- Many old materials superior to modern substitutes

- Workers today not as dedicated to quality

- Regulations, laws, wage packages put downward pressure on quality

- CLICK HERE to Get Tim's FREE & FUNNY Newsletter!

Less than two hours ago, I was having breakfast with a reporter from our local daily newspaper, The Laconia Daily Sun. It’s a wonderful small newspaper published in central New Hampshire. He was preparing a story about my new book Roofing Ripoff and asked me a fascinating question, “Are new homes built better than older homes?”

Complex Question - More Complex Answer!

Ten minutes later, I still hadn’t finished my answer. It’s a complex question and the answer requires lots of thought and examples. As I drove home from the interview I thought, “This would make a very good column topic.”

I could probably write a small book about this question so please understand this tiny column will not do the topic justice. Let’s get started.

Break Down Question

You need to break the question down into at least three parts to get to the answer. I maintain you need to look at the labor aspect, the materials and the overarching economics of the building industry to drive towards the correct answer.

Always Substandard Construction

Let’s start off by saying that years ago you could absolutely find poorly built homes. There were some builders and contractors back then that did bad work and the houses have since decayed.

I have no proof or data to back it up, but I have a feeling that low-quality contractors didn't last long years ago.

Free & Fast Bids

CLICK HERE to get FREE & FAST BIDS from local builders. Visit their work and judge their quality.

High Quality Is Everywhere

I can also take you to downtown Laconia, NH and show you a building that’s right next to the old train station. It’s our public library. (See photo above.) This magnificent stone structure is in excellent condition and it’s now approaching 120 years in age. It was built to last. Great magnificent buildings like this are in abundance in smaller towns and larger cities all over the USA. They might be homes or public buildings.

There are many older homes still in magnificent shape that are not as extravagant as the Laconia Public Library and they might be built with a mixture of stone, wood and stucco.

Growing Poor Quality Trend

It’s my guess my email Inbox would be considered by a PhD mathematician to be a statistically relevant sampling of the problems most homeowners face here in the USA. I get vast amounts of emails from homeowners who suffer from poor workmanship. I’d venture to say that today’s workforce in the residential construction industry, as a whole, is not as concerned about quality as the craftsmen from 150 years ago.

Vocation vs. Job

Back then many workers considered what they did a vocation. They made it a career choice and took lots of pride in what they did. Today it seems that many workers treat what they do each day as a job. There’s a vast difference between a vocation and a job.

Old vs New Materials

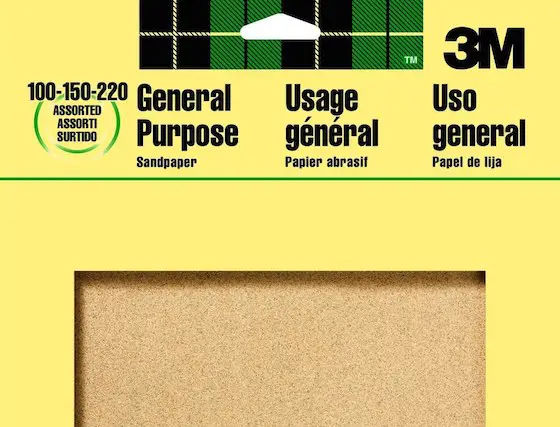

Let’s touch for a moment on materials. Look at the end of a piece of dimensional lumber like a 2 x 10 and note the width of the growth rings of the tree. You may shrug your shoulders. But those of us who have decades of remodeling experience can tell you that the lumber used in older homes was very much different than what you can get today.

I have pieces of old lumber taken from buildings built in the late 1800s. The light-colored growth rings that represent the wood added to the tree in the spring of each year are much narrower than those from modern trees.

New lumber is nothing like the lumber of old. Look at how wide the lighter-colored spring wood bands are in the timber to the left! (C) Copyright 2017 Tim Carter

The percentage of darker bands, summer wood, to lighter bands - spring wood in older lumber is almost equal. Today there’s much more spring wood in the hybridized lumber grown by the timber companies. Dark summer wood is more rot resistant and it’s stronger.

CLICK HERE to get FREE & FAST BIDS from local builders. Visit their work and judge their quality.

Plaster vs. Drywall

The reporter and I talked about plaster. You can take your fingernail and press on a modern wall made from drywall and create a depression. Try it. Forget about doing that to an older plaster wall.

A properly mixed plaster with a white lime finish coat has a compressive strength that approaches 3,000 pounds per square inch. In other words it’s rock-like material not something similar to cardboard.

Cast Iron Drains vs. PVC

I’ve been a master plumber since age 28. While there are many positive qualities to modern PVC drain pipes, I’ll take cast iron all day long.

Cast iron is soundproof, it’s fireproof and it’s much stronger. When you flush a toilet and the water cascades down a cast iron stack, you don’t hear Niagara Falls in your walls as you do with modern PVC pipe.

Great Modern Materials And Tools

Please don’t misunderstand me. There are many modern materials that are far superior to the materials of old.

We have better tools today that make us more productive and more accurate. But you need to have them in the hands of the people that are interested in producing the best product.

Complicated Economics

The overall economic issue is far harder to discuss and digest for us mere mortals who aren’t trained economists. The ever-rising standard of living here in the USA has put intense pressure on trying to keep the labor costs of building in check.

Regulations, laws, benefit packages, etc. that didn’t exist one hundred years ago add to the cost of building. To keep a job affordable something has to give. You can imagine what that might be.

High Quality Can Be Had

Fortunately if you have the budget and the time, you can build a home today that will last for centuries. It doesn’t have to be the Biltmore or some other extreme mansion.

There are still some builders and craftsmen that still know how to take available high-quality materials and create a home that will be far better than the baseline standard home I see being constructed today.

CLICK HERE to get FREE & FAST BIDS from local builders. Visit their work and judge their quality.

Column 1198