DEAR TIM: My husband and I are getting ready to build a new home. We want to spend as little as possible on heating and cooling fuel costs. 2 x 6 wall studs are two inches deeper than standard wall studs allowing you to add more insulation. How much does it really cost to increase the exterior wall thickness of a house? Is it worth the extra money? What else can we do to lower fuel costs? Karen V., Springfield, IL

DEAR KAREN: There are several things you need to consider when calculating the cost of increasing the exterior wall thickness of a house. The wall studs, top and bottom wall plates, insulation, and window and door extension jambs will all cost more money. Once you have calculated the total added cost, you need to calculate how soon you might receive a payback. The soundness of the investment depends upon where you live and how close you are to sea level.

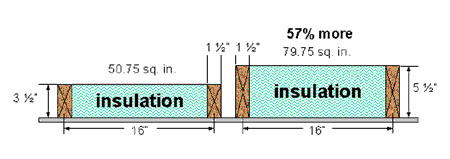

Depending upon the size of your home, the cost to upgrade from 2x4 to 2x6 exterior walls can be significant. I decided to see what the cost would be for a simple 60 foot long by 30 foot deep single story ranch house. The added cost for the wall studs and top and bottom plates amounted to $300. Window and door jamb depth needs to increased with 2x6 walls. These extension jambs cost $575 in my example. The extra thickness fiberglass insulation added $145 to the cost. The total up-charge for my hypothetical house would be $1,020. Larger houses or ones with more exterior wall surface area, windows, and doors will obviously cost more money.

To calculate the possible payback you need to determine how much fuel you will save by increasing the wall thickness. This is a very time consuming and complicated process. Thankfully some scientists at the Building Research Council at the University of Illinois at Urbana-Champaign have done this. The results of their research are fascinating.

The scientists discovered that two very important things impact the payback period on wall insulation thickness upgrades. The most important item is simple: How cold does it get where you live and how long does it stay cold? There is an accepted method for measuring this from one city to the next. It is called the degree day method. The meteorologists who work for the National Weather Service calculate this for each day of the heating season in your city.

Degree days are easy to calculate. You must determine the average temperature for each day of the heating season. Add together the recorded high and low temperature for each day and divide this sum by 2. Take this average daily temperature and subtract it from 65 degrees. The result is the total degree days for that date. As the weather gets warmer, you obviously have fewer degree days per day. When the average daily temperature is 65 degrees or more, you have 0 degree days for that date.

The scientists at the University of Illinois determined that if you live in an area that experiences 5,750 or more degree days per year, then it begins to make economic sense to switch to 2x6 exterior walls. The more heating degree days you have above 5,750 the faster your payback will occur.

Altitude above sea level also makes a difference. Those people who live closer to sea level experience a more rapid conductive heat loss through the air. Because the air is denser as you get closer to sea level, heat travels from air molecule to air molecule more quickly. For every 1,000 foot gain in altitude, 5 percent less heat is lost through conduction. This is one reason why solar energy houses work great in mountain areas and perform poorly in seaside situations. Houses at or near sea level need to be well insulated and tightly sealed.

People who live in the Sun Belt of the United States who tend to use air conditioners much more than furnaces face the same tough choices as you do. The cooler a person wishes the inside of their house to be, the more sense it makes to upgrade to 2x6 walls. A person who prefers an indoor temperature of 70 degrees F during the summer months will use considerably more energy than a person who can survive an indoor temperature of 76 degrees F. The added insulation that a 2x6 wall provides will allow the 70 degree house to achieve a much more rapid payback.

Probably the best way to save energy is to increase the amount of attic insulation. Heat loss is greatest through insulated ceiling areas. Consider upgrading your blown-in attic insulation to an R-value of 38 or higher. I have an R-58 attic insulation value in my own home. Windows and doors are the second greatest source of heat loss and heat gain. Purchase the best windows and doors you can afford. Look for ones that have the lowest air infiltration loss through the weatherstripping and the highest overall R-value. You should also invest in air infiltration barriers. These will block those toasty warm air molecules from escaping your magnificent new home during the winter months!