DEAR TIM: I belong to a health club and really enjoy relaxing in the steam room. Is it possible to create one of those in my house? Is it as simple as installing the steam generation unit? What is the best way to construct a steam enclosure? What do you know about the different steam generating units? Lana M., Cookeville, TN

DEAR LANA: Whooaa! You are going to be the most relaxed person in your town if you have one of these wonderful steam baths in your house. What's more, I'll bet you will have the cleanest skin in town. There simply is nothing quite like a steam bath to soothe a stressed soul.

The actual installation of a steam generation unit is not that hard. It requires moderate plumbing and electrical skills and the ability to follow directions. Many units now have electronic controls that allow you to set the desired temperature and the duration of your steam experience. Certain models have controls both inside and outside the steam area. They are easy to operate and tell you exactly what the temperature is and how many minutes of pleasure are left of your steam experience.

The key to a completely successful installation lies in the actual construction of steam bath or shower area. Steam is visible water vapor and it can penetrate into walls, ceilings, and floors and create rot problems. The trick is to block the movement of this water vapor, collect the water as it condenses, and then return the water into the shower or tub drain.

I feel the best way to build a residential steam room is to model it after the one at your health club, but downsize it for your needs. A 4 foot wide by 6 foot long shower area is ideal. You need to build in a seat at one end, so you can relax while the steam surrounds you. The walls, floor and ceiling should be tiled covered. You can't have any exposed plaster or drywall. If you do, it will soon deteriorate as it is attacked by the high temperature steam.

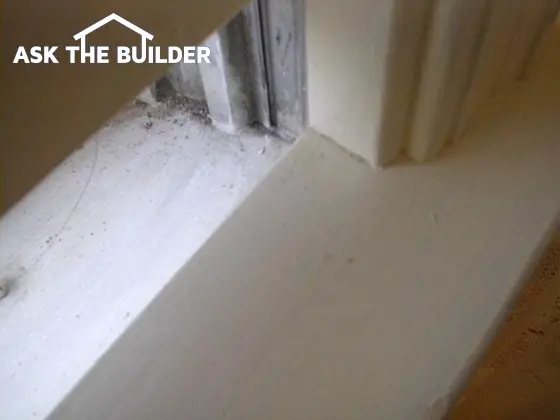

The tile floor should be installed using a cement base that sits on top of a chlorinated polyethylene (CPE) water barrier. This water and vapor proof material will act as the collection pan for any water that tries to escape from the steam room. The walls and ceiling must be covered with a single piece of high performance cross laminated polyethylene vapor barrier that is at least 6 mills thick. This vapor barrier material is nailed to the wall and ceiling framing members and drapes over the turned up edges of the shower floor CPE liner.

The next item that is installed is one half inch cement tile backer board. I like to leave a one eighth inch crack between pieces and then caulk this crack with 100 percent silicone caulk. The ceramic tile should be installed using thinset mortar, not the pre-mixed organic adhesives. Thinset is simply a cement based adhesive that will withstand many years of steam exposure. The organic adhesives might succumb to the constant high temperature steam assault.

You can't use a standard shower door for a steam room. The doors must be custom fit to your opening so that when closed, no steam can escape the shower area. The major shower door manufacturers make decorative doors for this very purpose.

Sizing a steam generation unit requires a little thought. Each manufacturer has several different sized units that are matched to the cubic feet of area in your steam enclosure, the type of wall surface and its construction, type of tub or floor, distance from the steam unit to the steam bath area, and whether the steam enclosure is adjacent to an exterior wall. It seems difficult, but the manufacturers have easy tables that guide you through the sizing process.

When selecting a steam unit, ask about the length of time it takes the steam to build within the room. Because of their internal design, some units make steam much faster than other units. Ask about the buildup of minerals on the internal components of the steam units. Some manufacturers have built their units so that they flush these minerals away at the end of each steam cycle. Read and reread the installation instructions. It is vitally important that you follow them to the letter to make sure the steam units work as designed.

Companion Articles: Steam Room Construction Tips, Steam Bath Unit Companies, Steam Bath Check Up

Column 275